Standard AA batteries are sufficient for remote controls, but they are the "weakest link" in industrial IoT, medical diagnostics, and smart grid sensors. Factory clients frequently encounter three major technical hurdles:

Voltage Sag: Traditional batteries drop voltage as they discharge, causing sensitive electronics to malfunction.

Thermal Instability: Extreme cold (-20°C) or heat (+60°C) leads to rapid capacity loss or safety risks.

Short Lifespan: Replacing batteries in remote sensors every 12 months increases the Total Cost of Ownership (TCO) for end-users.

As a solution-oriented AA Lithium ion battery manufacturer, Mottcell has re-engineered the AA cell to turn these bottlenecks into competitive advantages.

Whether your device requires a standard replacement or a high-power upgrade, Mottcell’s factory capabilities cover the full spectrum.

Many professional devices are calibrated for the 1.5V discharge curve of alkaline batteries but need the rechargeability of lithium. Our AA Lithium ion battery factory produces constant-voltage 1.5V lithium cells. By integrating a micro-buck converter within the cell, we solve the problem of "device shutdown" by providing a flat 1.5V output from 100% to 0% charge.

For devices requiring high burst currents:

3.7V Li-ion (14500): Optimized for energy density, solving the space constraint in compact medical tools.

3.2V LiFePO4: As a specialized 3.2V AA Lithium ion battery manufacturer, we provide the industry’s most stable chemistry for solar storage and telecom backup, ensuring the cell never exceeds safe thermal limits.

Mottcell is not just an AA Lithium ion battery supplier; we are an extension of your R&D department. Integration issues are the primary cause of project delays. We solve these through:

Tailored Terminations: Our AA Lithium ion battery factory can weld customized nickel tabs, PC pins, or high-drain wire leads (JST/Molex) to match your PCB footprint exactly.

Proprietary BMS Design: We develop specialized Protection Circuit Modules (PCM) in-house. This allows us to solve the "parasitic drain" problem, extending shelf-life for devices that remain in standby for months.

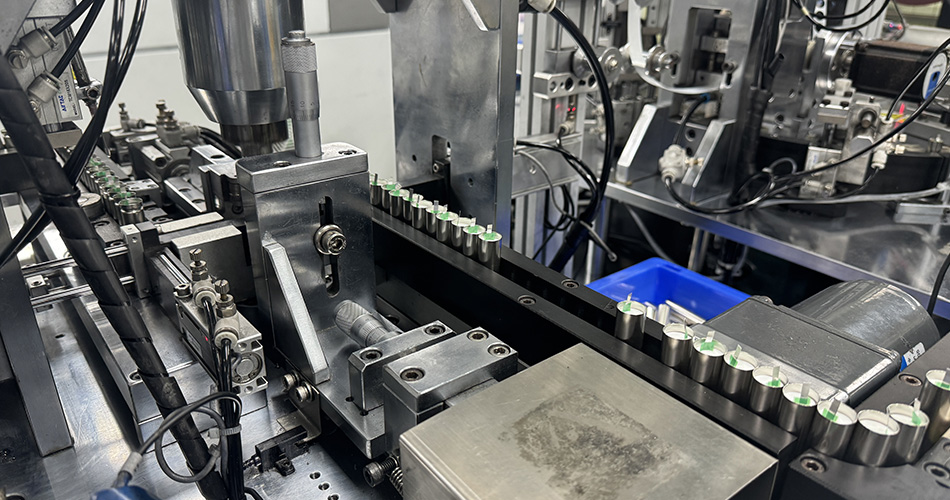

We solve the "MOQ Barrier" for startups while maintaining the capacity for giants. With 8 automated lines, we offer fast sampling (3-5 days) and scalable production that grows with your project.

For projects in mining, marine, or solar lighting, a standard battery is a liability. Mottcell’s role as a 3.2V AA Lithium ion battery manufacturer focuses on environmental resilience:

Extreme Temperature Cells: Our specialized electrolytes solve the "freezing" issue, allowing batteries to maintain 80% capacity at -20°C.

Extended Cycle Life: By using high-purity (99.9%) cathode materials, our 3.2V AA Lithium ion battery factory produces cells with over 2,000–4,000 cycles. For a factory client, this means their product stays in the field for 10 years instead of 2.

Exporting battery-powered products requires navigating a maze of safety standards. As your AA Lithium ion battery supplier, we provide a "One-Stop" certification solution:

UN38.3 & MSDS: Ensuring legal and safe global air/sea freight.

IEC62133, CE, & UL: Solving the compliance requirements for the EU and North American markets.

Full Traceability: Every cell from our 3.2V AA Lithium ion battery supplier facility is laser-coded, allowing us to trace raw material batches back to the source—a critical requirement for medical and automotive clients.

Q1: How does Mottcell solve the consistency issue in large-scale AA battery packs?

A: As a leading AA Lithium ion battery manufacturer, we use AI-powered sorting equipment to match cells by internal resistance (IR), voltage, and capacity within 1% variance. This prevents "weakest link" failure in multi-cell packs.

Q2: Can your AA Lithium ion battery factory provide waterproof enclosures?

A: Yes. We specialize in over-molding and ultrasonic welding to create IP65 or IP67-rated battery packs, solving the problem of moisture ingress in outdoor industrial applications.

Q3: What makes Mottcell a superior 3.2V AA Lithium ion battery manufacturer for solar lighting?

A: Our 3.2V AA Lithium ion battery factory optimizes the LiFePO4 chemistry specifically for daily deep-discharge cycles and high-temperature solar charging, resulting in a failure rate of less than 0.1% over 5 years.

Q4: How do you solve the safety risk of high-capacity lithium cells?

A: Beyond the stable LiFePO4 chemistry, we integrate CID (Current Interrupt Devices) and PTC (Positive Temperature Coefficient) resistors into our cells. As a professional 3.2V AA Lithium ion battery supplier, we ensure triple-layer protection (Chemical, Mechanical, and Electronic).

Q5: Why choose 1.5V Lithium over Ni-MH for smart locks?

A: Ni-MH has a high self-discharge rate. As an AA Lithium ion battery manufacturer, our 1.5V Li-ion cells have ultra-low standby drain and maintain 1.5V until the end, solving the "stuck lock" issue caused by the gradual voltage decline of Ni-MH.

Q6: What engineering support can I expect from a 3.2V AA Lithium ion battery supplier?

A: Mottcell provides full thermal simulation, discharge curve analysis, and BMS firmware customization. We solve the "Integration Gap" between your hardware and the power source.

Mottcell’s mission as an AA Lithium ion battery manufacturer is to provide more than just power; we provide certainty. Whether you are seeking a 3.2V AA Lithium ion battery manufacturer for extreme longevity or a high-capacity AA Lithium ion battery factory for global scale, our solutions are engineered to solve your specific industrial pain points.

Start Your Custom Project Today: Visit

Custom 14650 LiFePO4 Battery Manufacturer | High-Safety Slim LFP Cells

Wholesale 22650 LiFePO4 Battery Factory | Custom Industrial Packs

16340 Lithium-Ion Battery Manufacturer | Custom High-Drain RCR123A Cells

Reliable 18500 LiFePO4 Battery Manufacturer | Custom Compact LFP Cells

Best Rechargeable Batteries for Industrial OEM | 2026 Factory Guide

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

Custom 26700 Lithium-Ion Battery Manufacturer | High-Capacity OEM Packs

Reliable 14500 LiFePO4 Battery Manufacturer | Custom AA-Size LFP Cells