Lithium-ion batteries are a type of rechargeable battery that relies on lithium ions moving between the anode and cathode to store and release energy. These batteries are popular due to their high energy density, long cycle life, and low self-discharge rates. Their efficiency and reliability have made them the backbone of portable energy storage, powering everything from small gadgets to large-scale electric vehicles. However, not all lithium-ion batteries are created equal. Differences in size, voltage, and capacity mean that specific batteries are suited for different applications, which is why understanding the nuances of each type is crucial for selecting the right battery for the job.

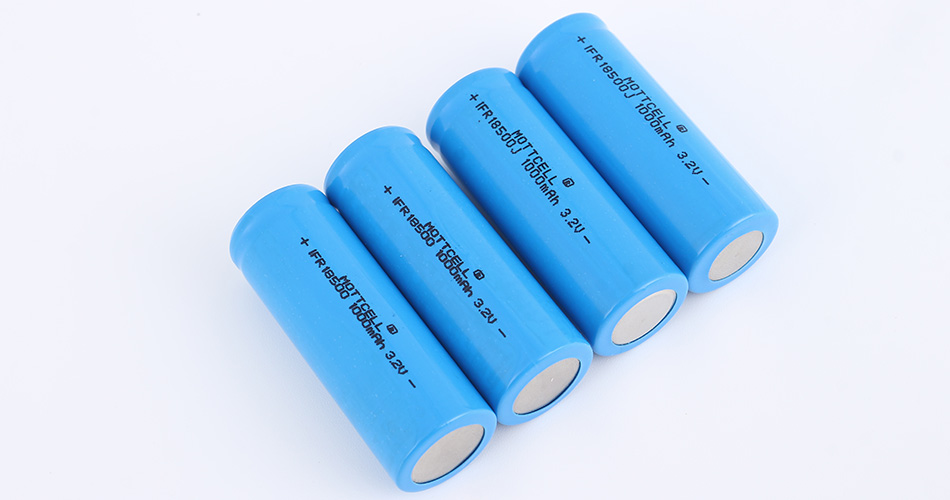

The 18500 lithium-ion cell is a cylindrical battery, measuring 18mm in diameter and 50mm in length. The "3.2V" part of its name refers to the nominal voltage of the battery. This compact size combined with a decent voltage output makes it particularly suitable for applications where space is limited but power cannot be compromised. This type of battery is often used in applications requiring a balance between size and power, such as portable electronics and certain power tools. Its versatility and reliability have made it a preferred choice in industries that demand both compact form factors and robust energy solutions.

The production of lithium-ion cells is a sophisticated process that requires precision and control. Each step in the manufacturing chain is meticulously planned and executed to ensure the final product meets high-performance standards. Factories dedicated to producing these batteries follow strict protocols to ensure quality and safety. This involves a combination of advanced machinery and skilled workforce, working in harmony to produce reliable batteries. Let's take a closer look at what goes on inside a 3.2V 18500 lithium-ion battery factory, where cutting-edge technology meets meticulous craftsmanship.

The first step in lithium-ion production involves processing raw materials. This includes the lithium compounds, which are essential for the battery's operation. These materials are carefully measured and mixed to create the electrode slurries. Each ingredient is sourced with precision to ensure consistency in quality, as even slight deviations can affect battery performance. The focus on raw material purity and accuracy ensures that the foundation of the battery's chemistry is solid and reliable.

The slurry is then coated onto metal foils to form the positive and negative electrodes. These foils are dried and compressed to ensure the electrodes have the right thickness and density. This stage is crucial because the quality of the electrode directly impacts the battery's efficiency and longevity. Precision is crucial here, as any variation can affect the battery's performance. Advanced machinery and techniques are employed to maintain uniformity and to optimize the electrochemical properties of the electrodes.

Once the electrodes are prepared, they are assembled into cells. This involves stacking or winding the electrodes, inserting separators, and enclosing everything in a casing. The process is highly automated to ensure consistency and minimize human error. The 18500 cells are typically cylindrical, requiring precise winding techniques to fit within their compact size. This stage ensures that the battery can deliver its power safely and efficiently, no matter the application.

After assembly, the cells are filled with an electrolyte solution that facilitates the movement of lithium ions. This step is pivotal in enabling the battery's charge and discharge cycles. The cells are then sealed to prevent any leakage, which could be hazardous. This sealing process is critical for ensuring the longevity and safety of the battery, as any breach could lead to performance issues or safety hazards.

Before the batteries can be shipped, they undergo a formation process. This involves charging and discharging the cells multiple times to stabilize their chemistry. This stage ensures that the batteries reach their optimal performance levels. Extensive testing follows to ensure each battery meets the required standards for performance and safety. Only after passing these rigorous tests are the batteries deemed ready for market, ensuring reliability for the end-users.

Quality control is a critical aspect of lithium-ion production. Factories implement rigorous testing and inspection procedures to catch any defects or inconsistencies. This not only ensures the safety of the batteries but also their reliability in various applications. Given the potential risks associated with battery failures, this step cannot be overlooked. Quality control teams use advanced diagnostic tools to monitor every aspect of the battery's performance, from energy output to thermal stability. The commitment to quality ensures that each battery is safe for use and performs as expected in any situation.

The 3.2V 18500 lithium-ion battery is versatile, finding its place in various applications. Its compact size and adequate power make it suitable for portable electronics, flashlights, and even certain medical devices. Additionally, these batteries are used in power tools that require a balance between size, weight, and power output. The adaptability of the 18500 battery means it can meet the needs of a wide range of industries, offering reliable power solutions in compact forms.

In the realm of portable electronics, size and weight are critical factors. Devices like smartphones, cameras, and handheld gadgets require batteries that do not add unnecessary bulk. The 18500 battery's compact form makes it ideal for gadgets like cameras and handheld devices, where space is limited. Its ability to deliver consistent power without compromising on size makes it a favorite among manufacturers of cutting-edge electronics.

For power tools, batteries need to deliver sufficient power without being cumbersome. The 3.2V 18500 battery strikes this balance, making it a popular choice in this sector. Its robust construction ensures it can withstand the high demands of power tools, providing both the energy needed for operation and the durability required for repeated use. This makes it a practical choice for both professional and DIY enthusiasts.

As renewable energy becomes more prevalent, the need for efficient energy storage solutions grows. The 18500 battery, with its reliable performance, is increasingly used in solar energy systems and other renewable energy storage applications. Its ability to store and discharge energy efficiently makes it a valuable component in the push towards sustainable energy solutions. As renewable technologies evolve, the role of the 18500 battery in energy storage is set to expand even further.

The future of 3.2V 18500 lithium-ion batteries looks promising, driven by continuous advancements in technology. Researchers are constantly exploring ways to enhance battery performance, increase energy density, and improve safety features. Innovations in materials science and engineering are paving the way for even more efficient and versatile battery designs. As technology evolves, we can expect these batteries to become even more efficient and versatile, meeting the demands of future technological advancements.

Potential innovations include the development of solid-state batteries, which promise higher energy densities and improved safety. Solid-state technology could revolutionize the battery industry by offering more stable and longer-lasting energy solutions. While these technologies are still in the research phase, they hold the potential to revolutionize the battery industry. As these advancements reach commercial viability, they could significantly enhance the performance of 3.2V 18500 batteries.

As with all lithium-ion batteries, environmental impact is a concern. Efforts are underway to improve recycling methods and reduce the ecological footprint of battery production. Factories are investing in sustainable practices to ensure that the production of 3.2V 18500 batteries is as eco-friendly as possible. By implementing greener manufacturing processes and promoting recycling, the industry aims to minimize its environmental impact while meeting the growing demand for lithium-ion batteries.

The 3.2V 18500 lithium-ion battery factory plays a vital role in the production of batteries that power our everyday lives. Through meticulous processes and stringent quality control, these factories produce reliable and efficient batteries suited for a wide range of applications. The commitment to excellence in manufacturing ensures that these batteries meet the highest standards of performance and safety. As technology continues to advance, the future of 3.2V 18500 batteries looks bright, promising even greater innovations and applications in the years to come. With ongoing research and development, these batteries are poised to meet the evolving energy needs of a rapidly advancing world.

Reliable 3.2V 18500 Battery Supplier | Quality & Efficiency

Top 18500 Cylindrical Battery Supplier Guide

Top 3.2V 18500 Cylindrical Battery Factory

18500 Cylindrical Battery Factory Insights

Reliable 3.2V 18500 Battery Manufacturer Insights

Top 18500 Cylindrical Battery Manufacturer & Supplier

Top 3.2V 18500 Lithium-Ion Battery Suppliers

Top 18500 Lithium Ion Battery Supplier Guide