For OEM and industrial products, battery sourcing is not simply about choosing a cell size—it is about building a reliable power foundation that can scale from samples to mass production without quality drift. The 32650 cylindrical format is widely used in long-runtime and durability-focused applications, and it has become a preferred option for many manufacturers building energy-related systems, backup modules, industrial equipment, and custom battery packs.

To succeed in these applications, you need more than a seller—you need a stable 32650 Lithium ion battery supplier that can deliver consistent cell performance, support pack engineering, and meet long-term supply requirements. In many industrial projects, buyers also actively search for 3.2V platforms because they prioritize safety stability and long cycle life. That is why evaluating a 3.2V 32650 Lithium ion battery supplier and verifying factory-level capability is increasingly important.

This article explains how OEM buyers should evaluate suppliers, what separates a true 32650 cylindrical battery manufacturer from a trading-style vendor, and how to qualify 3.2V systems for industrial reliability.

The 32650 format is a large cylindrical cell that offers strong capacity potential and a robust mechanical structure. For OEM systems, this translates into practical benefits:

Higher energy per cell can reduce total cell count

Fewer cells can simplify pack wiring and reduce weld points

Cylindrical structure improves mechanical stability and pack durability

Scalable assembly is easier to maintain with standardized formats

In industrial environments, reliability matters more than a single “high capacity” claim. OEM buyers need stable performance across batches, especially when building multi-cell packs where small differences in internal resistance can lead to imbalance, reduced usable energy, and accelerated aging.

That is why the quality discipline of your 32650 Lithium ion battery supplier directly impacts the lifecycle and safety of your final product.

Many buyers begin with the search term 32650 Lithium ion battery supplier because it covers a broad set of sourcing channels. But not all suppliers have the same ability to support OEM manufacturing requirements.

Some suppliers resell cells from multiple sources. This can be useful for short-term procurement, but it often introduces risk for long-term OEM programs: inconsistent batches, unclear traceability, and limited engineering support.

In contrast, a supplier who operates with manufacturer-level control behaves more like a 32650 cylindrical battery manufacturer partner. They can offer:

Batch consistency management

Traceability and change control discipline

Stable production capacity planning

Pack-level engineering support for OEM integration

For industrial products, choosing a supplier with true factory-level capability reduces risk and improves qualification speed.

One major sourcing mistake is treating “32650 lithium ion” as one single category. In real OEM projects, chemistry selection influences safety, charging logic, and long-term lifecycle.

These platforms are widely used when energy density is a priority. They can be effective in many devices, but they require careful protection design and thermal management, especially in larger-format cylindrical cells.

Many industrial systems prioritize long service life and stable operation. In these cases, buyers often prefer working with a 3.2V 32650 Lithium ion battery supplier and may also want a 3.2V 32650 cylindrical battery manufacturer that understands chemistry-specific system matching.

From an OEM perspective, 3.2V systems are often selected because they can support:

Safety-first product requirements

Long cycle operation with reduced degradation

Stable voltage output under load

Better tolerance for demanding environments

However, these benefits depend on correct charge cutoffs, discharge limits, and protection thresholds. That is why a 3.2V sourcing program should always include factory-level engineering communication, not just a datasheet review.

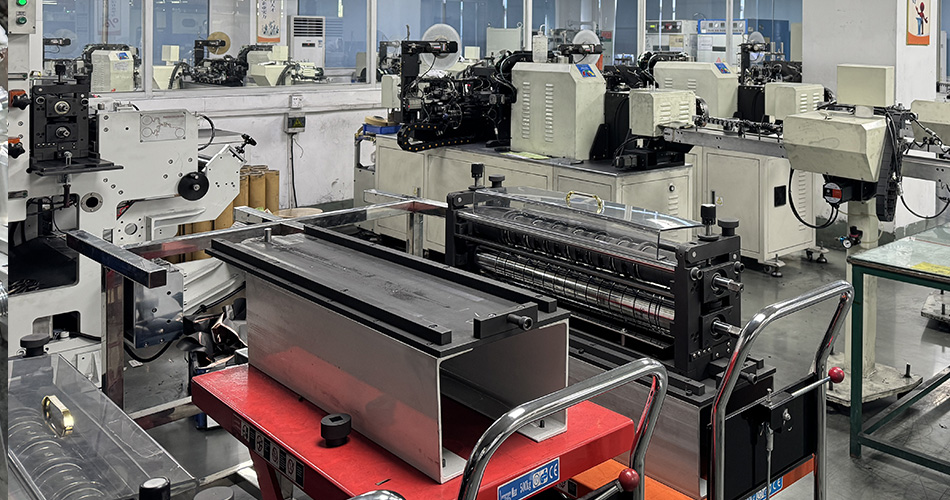

Whether you buy cells or finished packs, OEM success depends on manufacturing process maturity. A true 32650 cylindrical battery manufacturer should be able to explain how they control quality and consistency from start to shipment.

For multi-cell packs, consistency in capacity and internal resistance is essential. A professional factory should implement grading standards and clearly explain how they:

Sort and match cells for series packs

Handle outliers to reduce imbalance risk

Maintain consistent performance across production lots

Most OEM projects require custom packs. A mature supplier should support:

Series/parallel configuration recommendations

BMS or protection integration

Connector and wiring customization

Mechanical insulation and reinforcement

Guidance for thermal and mechanical design in industrial environments

This pack capability is often the difference between a battery that works in the lab and a battery that performs reliably in the field.

Field failures often come from assembly defects rather than cell chemistry: weak welds, insulation damage, polarity errors, or connector strain issues. OEM-grade factories reduce these risks with standardized inspection steps and end-of-line verification.

Industrial buyers often specify 3.2V platforms when they want safety stability and long cycle value. This is common in:

Backup power modules

Energy storage systems

Solar and off-grid products

Industrial monitoring and control equipment

Portable power units for demanding environments

In these projects, a 3.2V 32650 cylindrical battery manufacturer is expected to provide not only cells, but also system-level guidance: charge strategy, protection thresholds, current capability, and pack-level matching. Without this support, system mismatch becomes a major cause of performance issues.

To receive accurate proposals from a 32650 Lithium ion battery supplier, OEM buyers should provide:

Chemistry requirement (standard platform or 3.2V platform)

Target pack voltage and capacity

Continuous discharge current and peak discharge current

Size constraints and integration drawings if available

Connector and wiring requirements

Operating temperature range and environment risks

Expected order volume and project timeline

Clear RFQ inputs help suppliers recommend a safe, mass-production-ready configuration rather than a generic quote.

A 32650 Lithium ion battery supplier provides 32650 cylindrical cells and often custom battery packs for OEM and industrial applications. Reliable suppliers support consistent quality, traceability, and scalable supply.

A 3.2V 32650 Lithium ion battery supplier is preferred when safety stability, long cycle life, and predictable discharge behavior are critical. This platform is commonly used in industrial and energy-related systems.

A true 32650 cylindrical battery manufacturer demonstrates factory-level control over production processes, cell grading discipline, stable testing standards, and the ability to scale supply without quality drift.

To qualify a 3.2V 32650 cylindrical battery manufacturer, confirm chemistry expertise, system-matching support, consistent grading for pack assembly, standardized testing, and stable production capacity for repeat OEM orders.

Choosing the right 32650 Lithium ion battery supplier is one of the most effective ways to reduce field failure risk and protect your production schedule. Whether you are sourcing standard cylindrical cells or selecting a 3.2V 32650 Lithium ion battery supplier for safety-first industrial systems, the best outcomes come from factory-level process discipline, engineering collaboration, and scalable supply capability.

Efficient 3.2V 16340 Rechargeable Batteries Guide

High-Quality 3.2V 16340 Lithium Ion Battery Factory

LFP 3.2V AAA Rechargeable Battery Manufacturer: High-Voltage Precision for Compact Devices

AAA Lithium Ion Battery Factory: Specialized 3.2V LiFePO4 Production Base

14650 Rechargeable Battery Factory: Power & Innovation

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

32700 Lithium Ion Battery Manufacturer for OEM Applications

26700 Lithium Ion Battery Manufacturer for OEM Applications