In the competitive world of industrial manufacturing and product design, the "Alkaline vs Rechargeable" debate is more than just a matter of price—it’s a strategic choice that affects machine downtime, maintenance overhead, and total cost of ownership (TCO). For factory procurement managers and engineers, selecting between high-performance lithium batteries vs alkaline batteries is the foundation of a reliable power system.

As a premier power solution provider, Mottcell specializes in bridging the gap between standard disposable options and high-cycle rechargeable systems. This guide provides a deep dive into the engineering differences between primary and secondary cells to help you optimize your industrial equipment.

The most common question in battery maintenance is: are aa alkaline batteries rechargeable? The short answer is no. Standard alkaline batteries are "primary" cells, meaning their chemical reaction is irreversible. Attempting to recharge them in a standard charger can lead to potassium hydroxide leakage, corrosion, or even rupture.

For industrial environments that require constant power, the transition to aa rechargeable lithium batteries or NiMH alternatives is essential. While an alkaline battery is convenient for "set and forget" low-drain devices like smoke detectors, any high-drain industrial tool will quickly exceed the cost of a rechargeable system in under a year of operation.

When comparing lithium batteries vs alkaline batteries for OEM applications, the differences in energy density and thermal stability are stark.

Alkaline batteries start at 1.5V but drop linearly as they discharge. In contrast, lithium vs alkaline batteries performance shows that lithium maintains a stable voltage (around 1.5V for regulated cells or 3.7V for Li-ion) until the very end of the cycle. This ensures that industrial sensors and wireless transmitters operate at peak precision throughout the battery's life.

For factories with extreme operating conditions, lithium batteries vs alkaline batteries is an easy choice.

Alkaline: Performance drops significantly below 0°C (32°F).

Lithium: Can operate reliably from -40°C to 60°C (-40°F to 140°F), making them the industry standard for outdoor monitoring and cold-storage logistics.

In heavy-duty equipment like large flashlights, high-torque motors, and automated dispensers, "D" cells are the workhorses. Switching to d batteries rechargeable systems is the single most effective way to reduce industrial waste.

Professional d batteries rechargeable cells (NiMH) typically offer capacities between 8,000mAh and 12,000mAh. When sourcing rechargeable batteries d batteries, it is vital to check the mAh rating; many "consumer-grade" rechargeables are merely AA cells in a large plastic shell. Mottcell’s best d cell rechargeable batteries provide full-volume chemical capacity to ensure maximum runtime for industrial gear.

A robust rechargeable d batteries and charger setup is a "one-time" investment. By utilizing a smart industrial charger, factories can maintain a rotation of cells, ensuring that equipment never sits idle.

For handheld scanners, digital multimeters, and walkie-talkies, the aaa batteries rechargeable nimh format is the standard.

The rechargeable ni mh batteries aaa are favored over lithium in some handheld devices because they provide a stable 1.2V that mimics the alkaline discharge curve but without the waste. However, for "high-tech" handhelds requiring lighter weight and faster charging, a rechargeable aa lithium battery (or AAA equivalent) is increasingly becoming the preferred OEM specification.

Procuring the right cells is only half the battle. To truly lower costs, you must know how to maximize battery life across your facility.

Temperature: Store all cells in a cool, dry place (ideally 15°C). Avoid storing batteries near heaters or in direct sunlight.

Partial Charge: For long-term storage of lithium cells, maintain them at 40-50% charge to prevent capacity degradation.

Avoid Deep Discharge: Do not let your NiMH or Lithium cells drop to 0%. Recharging when they hit 20% can nearly double the total cycle life.

Clean Terminals: Periodically clean the contact points of both the rechargeable d batteries and charger to prevent resistance buildup, which causes overheating.

The primary difference between lithium and alkaline batteries lies in the chemistry. Alkaline uses zinc and manganese dioxide (disposable), while lithium uses lithium metal or ions. Lithium offers 2x higher energy density, performs in extreme cold, and is significantly lighter.

To maximize battery life, avoid "trickle charging" for extended periods and keep operating temperatures below 30°C. For lithium-ion packs, using a smart BMS (Battery Management System)—a specialty of Mottcell—is the best way to prevent the overcharging that kills cell health.

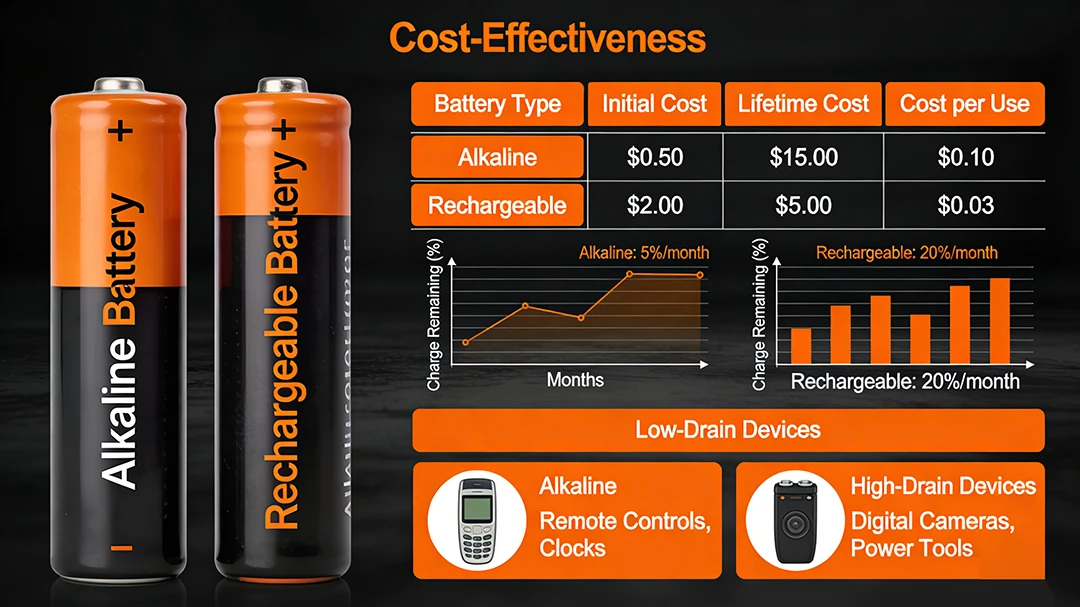

The difference between alkaline and rechargeable batteries is the reversibility of the chemical reaction. Alkaline batteries are discarded after one use, while rechargeable (NiMH or Li-ion) cells can be reused 500 to 2,000 times. From an industrial perspective, rechargeable systems offer a much lower TCO (Total Cost of Ownership).

The best d cell rechargeable batteries are those with Low Self-Discharge (LSD) technology. Mottcell produces high-capacity NiMH D cells that retain up to 85% of their charge even after a year of storage, making them perfect for emergency industrial equipment.

For modern factories, NiMH (Nickel-Metal Hydride) is far superior to NiCd because it lacks the "memory effect" and has a higher energy density. Mottcell provides high-performance NiMH D cells that are eco-friendly and offer superior discharge currents for heavy machinery.

Choosing between battery types: alkaline vs rechargeable doesn't have to be complicated. If your application is low-drain and infrequent, alkaline may suffice. However, for almost every modern industrial application, the efficiency and longevity of aa rechargeable lithium batteries or high-capacity d batteries rechargeable systems will save your factory thousands in the long run.

Related News

14650 Rechargeable Battery Factory: Power & Innovation

26700 Rechargeable Battery Manufacturer for OEM Applications

4860 Rechargeable Battery Manufacturer for High-Performance OEM Packs Meta Description

10440 Rechargeable Battery Factory Insights

14500 Rechargeable Battery Factory Insights

26700 Rechargeable Battery Manufacturer for OEM Applications

AAA Cylindrical Battery Manufacturer for OEM Factories

Popular Battery Sizes & Ratings: The Strategic Industrial Guide | Mottcell

Lithium Battery Safety & Usage: Industrial Guide for Factories

Battery Types: Alkaline vs Rechargeable Industrial Guide | Mottcell

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell