In the rapidly advancing world of industrial automation, medical devices, and portable electronics, power is the heartbeat of innovation. For factory managers, procurement specialists, and product engineers, the challenge isn't just finding a power source—it is about comparing rechargeable battery types to find the perfect balance between energy density, safety, and cost-efficiency.

Selecting the wrong chemistry can lead to catastrophic failures, from short lifecycles to the dreaded lithium ion battery swelling. As a globally recognized leader in battery technology, Mottcell provides this comprehensive guide to help industrial clients navigate the complexities of modern electrochemical storage.

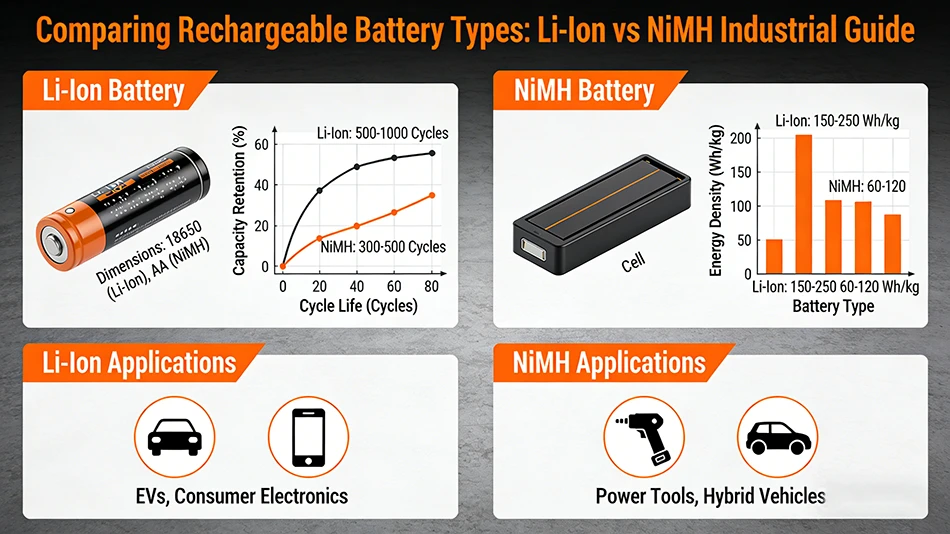

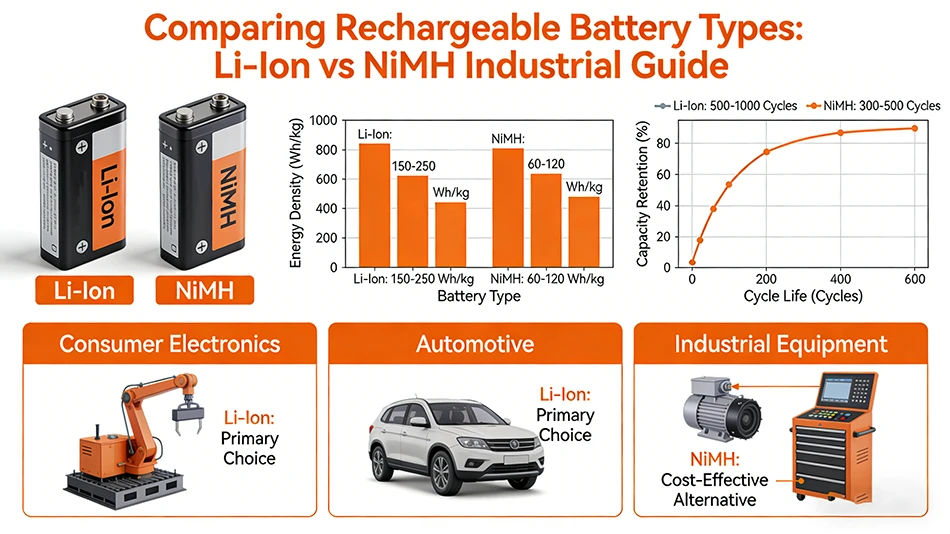

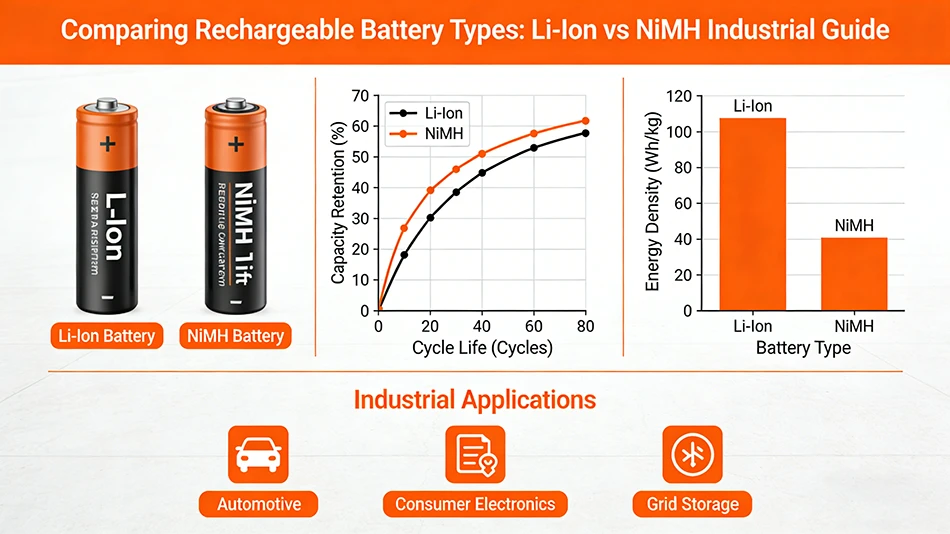

The most common debate in industrial procurement today is li ion battery vs ni mh. While both are rechargeable, they serve vastly different purposes based on their chemical properties.

Lithium-ion is the king of high energy density. It provides more power in a smaller, lighter package.

Pros: High voltage (3.6V/3.7V), no "memory effect," and high energy density.

Cons: Higher cost and sensitivity to extreme temperatures.

Nickel metal hydride is often considered the "safe" workhorse.

Pros: Lower cost, safer transport regulations, and excellent performance in low-drain applications.

Cons: Lower energy density and a higher self-discharge rate compared to lithium.

When comparing rechargeable battery types, factories must consider the "Total Cost of Ownership." While a li ion battery vs ni mh comparison shows lithium is more expensive upfront, its longer cycle life often makes it more economical for high-use industrial equipment.

In many legacy factory systems, you will still find Nickel-Cadmium (NiCd) cells. However, the shift toward ni cd battery vs ni mh battery is almost complete in modern manufacturing.

Once the standard for power tools, NiCd batteries are being phased out due to the "memory effect" (where the battery "remembers" a lower capacity if not fully discharged) and environmental concerns regarding toxic cadmium.

The nickel cadmium vs nickel metal hydride evolution was driven by the need for higher capacity—NiMH offers up to three times the capacity of NiCd in the same size—and a much greener chemical profile. If your factory is still using legacy nickel batteries vs lithium systems, upgrading to NiMH is the first step toward modernization.

For many industrial sensors and specialized tools, the physical size of the battery is as important as its chemistry.

Many industrial handheld devices still rely on the "C" format. Standard alkaline C batteries are wasteful for high-usage environments. Switching to c cell rechargeable NiMH cells allows a factory to reuse the same power source hundreds of times, drastically reducing hazardous waste. These rechargeable batteries c batteries are ideal for high-drain devices like large flashlights and automated test equipment.

A relatively recent innovation is the lithium 1.5 v battery. Unlike standard 3.7V lithium cells, these are engineered with internal circuitry to output a constant 1.5V, making them a direct, high-performance replacement for alkaline AA or AAA batteries in sensitive industrial controllers.

Even the smallest components in a factory—like CMOS backups or IoT sensors—require reliable power. The cr2032 battery rechargeable (also known as the LIR2032) is the lithium-ion version of the popular coin cell.

While a standard CR2032 is primary (non-rechargeable), the cr2032 rechargeable battery allows for solar or kinetic energy harvesting within small devices. As a leading cr2032 battery rechargeable provider, Mottcell ensures these tiny cells maintain the high cycle life required for long-term industrial deployments.

One of the biggest risks in the industrial sector is li ion battery swelling or lithium battery swelling.

Lithium ion battery swelling is usually the result of "off-gassing." This happens when the battery is:

Overcharged: Exceeding the voltage limit.

Exposed to Heat: Operating in poorly ventilated factory environments.

Deeply Discharged: Allowing the voltage to drop too low, causing chemical decomposition.

To prevent lithium battery swelling, Mottcell integrates advanced Battery Management Systems (BMS) into our packs. Choosing reliable battery suppliers who prioritize BMS engineering is the only way to ensure factory floor safety.

In the debate of battery vs capacitor, the answer depends on the duration of power needed.

Battery: Stores a large amount of energy and releases it slowly over time. Best for continuous operation.

Capacitor (Supercapacitor): Stores less energy but can release it almost instantly and recharge in seconds. Best for regenerative braking in factory AGVs or rapid-fire industrial sensors.

The global market is flooded with low-grade cells. For industrial OEMs, the criteria for selecting battery suppliers should include:

Compliance: Do they hold UL, CE, RoHS, and UN38.3 certifications?

Consistency: Can they provide cells with matched internal resistance for large packs?

Innovation: Do they offer both lithium battery vs nickel metal hydride solutions to cover all your use cases?

Mottcell stands out among battery suppliers by offering vertically integrated manufacturing, from the raw chemical formulation to the final li ion battery swelling prevention testing.

While Li-ion is lighter, NiMH is incredibly durable and performs better in extreme temperature swings without requiring complex cooling systems. For certain industrial "set-and-forget" backup systems, ni mh battery vs lithium is a choice made for longevity over weight reduction.

There is no single "best" battery; it depends on the application. For high-capacity, lightweight needs (like drones or laptops), lithium ion is best. For cost-sensitive, low-drain, or high-safety environments (like backup lighting), NiMH is often the better choice.

Absolutely not. The lithium battery vs nickel metal hydride comparison alone shows massive differences in voltage (1.2V vs 3.7V), energy density, and charging requirements. Using the wrong charger for the wrong chemistry can lead to fire or lithium battery swelling.

Lithium is better for energy density and weight. NiMH is better for cost, environmental impact, and safety in high-heat environments. Mottcell provides both to ensure our clients have the right tool for the job.

Comparing rechargeable battery types is a complex but necessary process for any factory looking to optimize its operations. Whether you are transitioning from nickel batteries vs lithium, looking for a reliable cr2032 rechargeable battery, or designing a custom battery vs capacitor hybrid system, Mottcell is your technical partner.

Ready to power your next project? Contact Mottcell today for a technical consultation and factory-direct quote on our full range of industrial battery solutions.

Related News

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

14650 Rechargeable Battery Factory: Power & Innovation

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

AAA Lithium Ion Battery Factory: Specialized 3.2V LiFePO4 Production Base

LFP 3.2V AAA Rechargeable Battery Manufacturer: High-Voltage Precision for Compact Devices

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer