In the industrial world, power is the heartbeat of every innovation. Whether you are an OEM engineer designing the next generation of portable medical devices or a fleet manager overseeing power solutions for industrial vehicles, the choice between lithium polymer vs lithium ion technology is fundamental.

As a global leader in battery manufacturing, Mottcell understands that choosing the right energy storage platform isn't just about capacity—it’s about optimizing for safety, form factor, and long-term reliability. This comprehensive guide explores the core differences between lithium ion polymer and traditional lithium ion technologies, specifically tailored for factory-level decision-makers.

To understand the debate of lithium polymer vs lithium ion, we must first define the newcomer. What is a LiPo battery? Short for Lithium-Ion Polymer, the LiPo battery is essentially a refined version of the traditional lithium-ion cell.

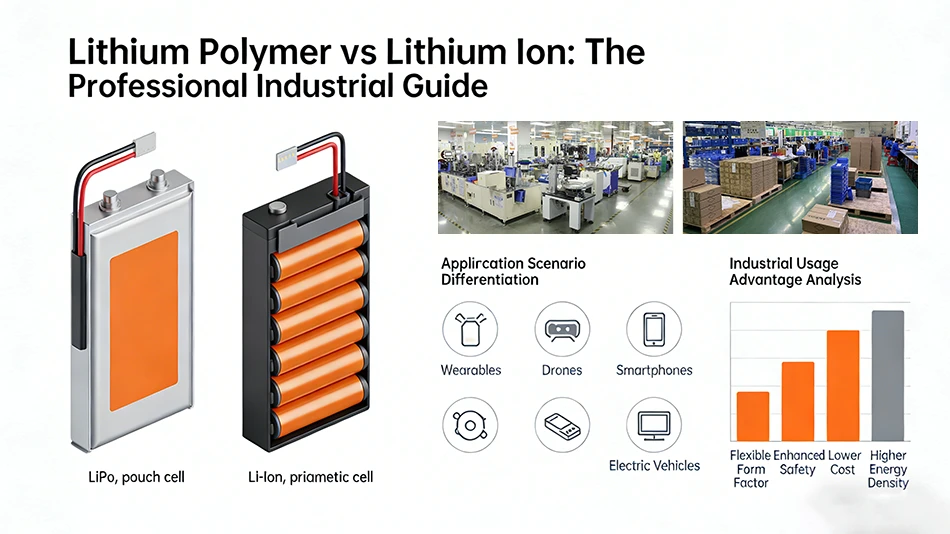

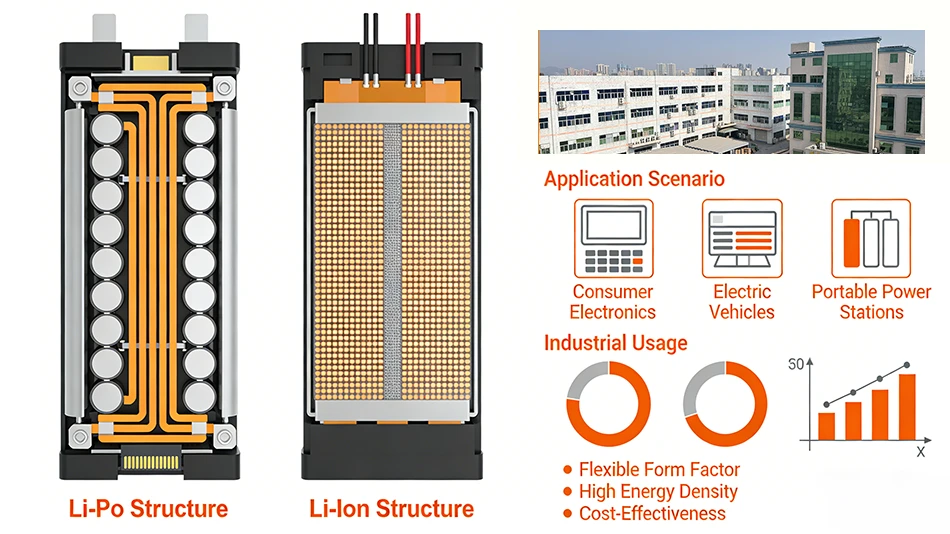

Unlike standard lithium-ion batteries that use a liquid electrolyte held in a rigid metal casing, a lithium ion polymer battery utilizes a gel-like or solid polymer electrolyte. This chemical evolution allows for the "pouch cell" design—a flexible, aluminum foil-style packaging that eliminates the need for heavy, fixed-size metal cans. For industrial designers, this means the ability to create ultra-thin or irregularly shaped power packs that were previously impossible.

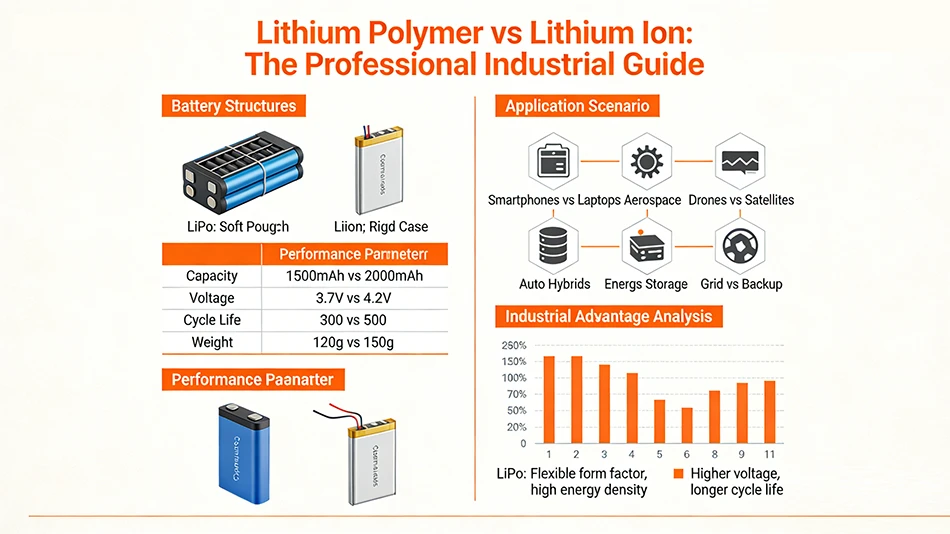

When evaluating lithium ion polymer vs lithium ion for factory applications, engineers typically focus on three pillars: energy density, structural integrity, and cost-efficiency.

Standard lithium ion batteries are known for their exceptional energy density, making them the workhorse for high-capacity needs like power tools and large-scale energy storage. However, lithium polymer li poly batteries often offer higher specific energy (Wh/kg) because their lightweight pouch packaging reduces dead weight.

The most significant advantage of lithium ion polymer is its form factor. While lithium-ion cells are typically limited to cylindrical (like 18650s) or prismatic shapes, a lithium ion polymer battery can be manufactured in almost any size. This is critical for wearable tech, drones, and slim-profile handheld industrial scanners.

| Feature | Lithium Ion (Liquid) | Lithium Polymer (Gel/Solid) |

| Electrolyte | Liquid Organic Solvent | Gel or Solid Polymer |

| Casing | Rigid Metal (Steel/Alu) | Flexible Aluminum Pouch |

| Shape | Standardized (Cylindrical/Prismatic) | Highly Customizable/Thin |

| Safety | Risk of Leakage; Thermal Runaway | Resists Leakage; Risk of Swelling |

| Cost | Lower (High Production Maturity) | Higher (Complex Manufacturing) |

| Durability | High (Rigid Shell) | Moderate (Requires External Protection) |

One of the fastest-growing sectors for advanced battery technology is the mobile industrial and leisure market. The shift toward a lithium ion battery for rv (Recreational Vehicles) and AGVs (Automated Guided Vehicles) is driven by the need for deep-cycle performance.

Many factories and fleet managers are moving away from 12v lead acid batteries. While a 12v lead battery is inexpensive upfront, its limitations are clear:

Weight: A typical lithium ion battery for rv is 60% lighter than a lead-acid equivalent.

Depth of Discharge (DoD): You can use 100% of a lithium battery's capacity, whereas 12v lead acid batteries should not be discharged below 50% without damaging the cells.

Charging Speed: Lithium-based lithium ion rv batteries charge up to 4x faster than lead-acid, minimizing downtime.

At Mottcell, our lithium ion rv batteries utilize LiFePO4 (Lithium Iron Phosphate) chemistry within the lithium-ion family, providing a 10-year lifespan that far outlasts any traditional 12v lead battery.

For factory-level clients, the question of lithium ion or polymer safety is paramount.

Lithium ion batteries are structurally robust but carry a higher risk of "thermal runaway" if the liquid electrolyte is compromised.

Lithium polymer vs lithium ion safety often comes down to the failure mode. LiPo batteries are less likely to leak liquid, but they are prone to "swelling" if mistreated or overcharged.

Mottcell integrates advanced Battery Management Systems (BMS) into every lithium ion polymer battery and cylindrical pack we produce. This ensures real-time monitoring of voltage, temperature, and current, mitigating the risks inherent in high-energy lithium chemistries.

From a procurement perspective, the choice between lithium ion battery vs polymer is often a balance of the bottom line and performance requirements.

Mass Production: If your product can accommodate a standard cylindrical shape, the lithium ion battery is the most cost-effective choice due to global manufacturing scales.

Specialized Design: If your product requires a unique "thin-film" profile or ultra-lightweight components, the investment in a lithium ion polymer solution is justified.

TCO (Total Cost of Ownership): Whether you choose lithium ion or polymer, both represent a massive saving over 12v lead acid batteries when considering replacement cycles, maintenance, and energy efficiency over 5-10 years.

People choose lithium polymer li poly batteries primarily for their lightweight and flexible form factor. They allow for thinner device profiles and are excellent for high-discharge applications like drones and high-end consumer electronics where space is at a premium.

Absolutely. Switching from 12v lead acid batteries to lithium ion rv batteries provides twice the usable power, faster charging, and a weight reduction that improves vehicle fuel efficiency. Mottcell’s LiFePO4 RV solutions are a "set and forget" investment for industrial fleets.

While they are part of the same chemical family, they are not the same. The primary difference is the electrolyte—liquid for Li-ion and gel/solid polymer for LiPo. This difference dictates their shape, safety profile, and packaging.

Lithium Cobalt (LCO) is a high-energy-density chemistry often found in Li-ion cells. It is generally more volatile than lithium polymer vs lithium ion variants like LFP (Lithium Iron Phosphate). Mottcell prioritizes safety by focusing on LiFePO4 and NMC chemistries with robust protection circuits.

Yes, thousands of industrial clients have successfully replaced their 12v lead battery banks with Mottcell’s 12V LFP (LiFePO4) packs. Users report better performance under load and zero maintenance requirements compared to traditional lead-acid.

LiPo batteries are safe when handled correctly and manufactured to high standards. Their most common "failure" is swelling rather than explosion. Mottcell ensures safety through high-quality separators and integrated BMS that prevent the overcharging that leads to gas buildup.

The debate between lithium polymer vs lithium ion isn't about which is "better," but which is right for your specific industrial application. At Mottcell, we pride ourselves on being more than just a lithium ion polymer battery manufacturer.

Related News

32650 Lithium Ion Battery Manufacturer for OEM Custom Cells and Packs

10440 Lithium Ion Battery Factory: Inside Look

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

16340 Lithium-Ion Battery Manufacturing Process

Top 18500 Lithium Ion Battery Manufacturer Guide

26700 Lithium Ion Battery Manufacturer for OEM Applications

32700 Lithium Ion Battery Manufacturer for OEM Applications

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer