In the modern industrial landscape, power is the heartbeat of innovation. The Lithium ion battery has revolutionized how we design, manufacture, and utilize technology, moving from a niche component to the primary energy source for global infrastructure. For factory owners, procurement managers, and OEM engineers, choosing the right battery technology is no longer just a technical choice—it is a strategic business decision that impacts product reliability, safety, and long-term ROI.

As a leading Lithium ion battery manufacturer, Mottcell understands the complexities of the B2B supply chain. In this guide, we will explore the technical superiority of lithium-ion systems and provide the insights needed for successful industrial sourcing.

Today, lithium ion batteries are the gold standard for portable and stationary energy. Their high energy density, low self-discharge rate, and ability to handle high-current loads make them indispensable. For factories developing smart devices, medical tools, or automated machinery, the transition from legacy chemistries to lithium-ion is the fastest way to gain a competitive edge.

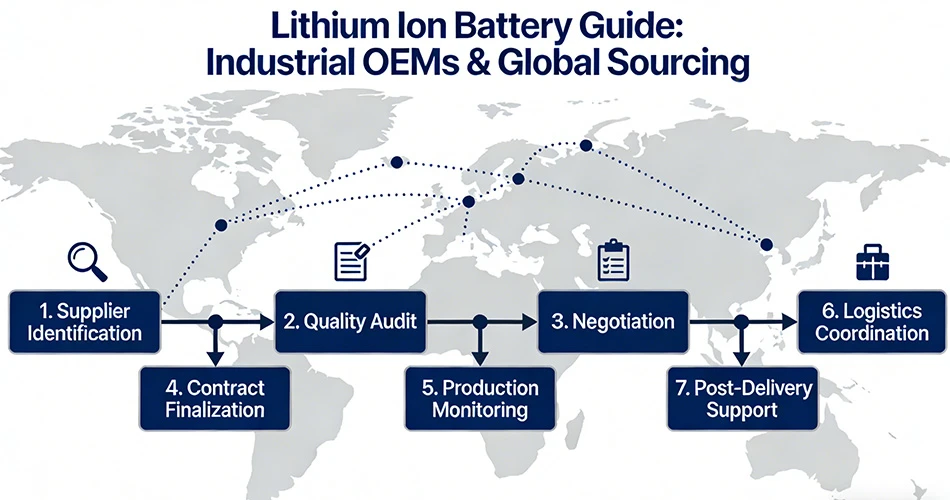

When you partner with a high-end Lithium ion battery factory, you aren't just buying cells; you are accessing an ecosystem of engineering support, safety certifications, and customized energy solutions designed to meet the rigors of industrial use.

One of the most frequent questions from industrial designers is why they should switch from traditional primary cells to a rechargeable Lithium ion battery vs alkaline solution.

Cycle Life: Alkaline batteries are single-use, creating massive waste and recurring costs. A professional-grade lithium-ion cell can provide 500 to 2,000 charge-discharge cycles.

Voltage Stability: Alkaline batteries suffer from a steady voltage drop during use. In contrast, a lithium-ion cell maintains a stable voltage for the majority of its discharge cycle, ensuring that precision electronics—like those in medical diagnostics—function consistently.

Total Cost of Ownership (TCO): While the initial investment in a lithium system is higher, the cost-per-use is a fraction of that of alkaline systems.

For any factory looking to improve sustainability and lower end-user costs, the lithium ion battery vs alkaline debate ends with lithium as the clear winner.

The 12v lithium ion battery has become a versatile powerhouse for industrial and commercial applications. Often used to replace heavy, inefficient lead-acid batteries, these 12 volt ion lithium batteries offer a significant reduction in weight while doubling the usable energy.

At Mottcell, our Lithium ion battery factory specializes in creating 12V modules that feature:

Built-in BMS (Battery Management System): Protecting against over-voltage, under-voltage, and short circuits.

Modular Design: Allowing factories to scale energy capacity by connecting modules in parallel or series.

Deep Cycle Performance: Our lithium ion deep cycle battery designs are perfect for applications where the battery is frequently discharged and recharged, such as in warehouse AGVs (Automated Guided Vehicles).

The automotive and logistics sectors are undergoing a massive shift. The lithium ion car battery is no longer just for luxury EVs; it is finding its way into industrial forklifts, terminal tractors, and heavy-duty factory transport vehicles.

Compared to traditional starter batteries, a lithium ion car battery offers:

Faster Cranking Amps: Reliable starts in extreme temperatures.

Weight Reduction: Improving vehicle handling and reducing wear on suspension systems.

Faster Recharging: Reducing downtime during multi-shift operations.

The "Van Life" and mobile office movements have driven a surge in demand for the lithium ion battery for motorhome and specialized mobile units. For manufacturers of recreational vehicles or mobile labs, lithium-ion provides a maintenance-free energy source that is significantly lighter than lead-acid or GEL batteries.

A lithium ion battery for motorhome use allows users to run high-load appliances like air conditioners or induction cooktops without the fear of damaging the battery through deep discharge—a common failure point in older battery types.

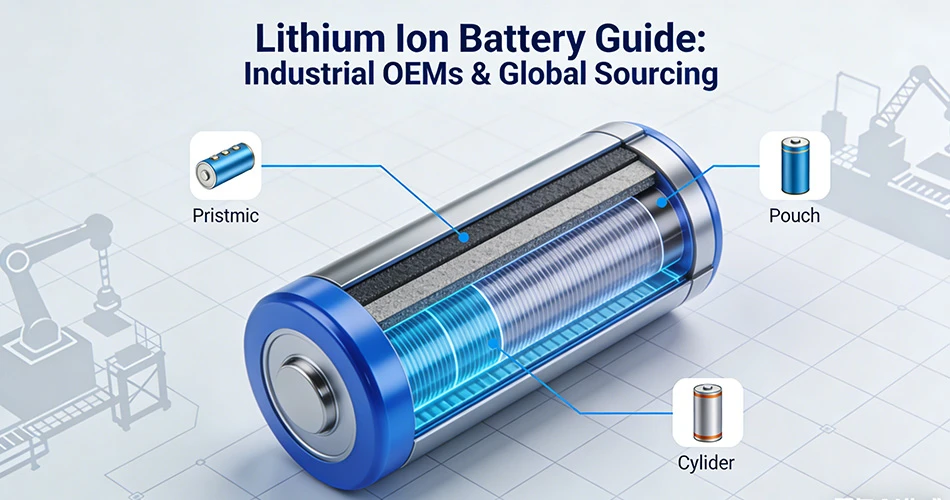

In the world of high-performance electronics, choosing between a lithium ion battery vs li polymer battery (often called lipo) is a common challenge for engineers.

Lithium Ion (Cylindrical): Best for high-capacity, standardized applications like 18650 or 21700 packs. They offer a rigid protective shell and are generally more cost-effective for large-scale industrial projects.

Li Polymer (Lipo): Known for being thinner and flexible. When comparing lithium ion battery vs lipo, Lipo is often the choice for ultra-slim devices, though they require more careful management to prevent swelling.

As a specialized Lithium ion battery supplier, Mottcell helps OEMs navigate these choices to find the perfect balance between form factor and energy density.

A battery is only as good as the system that charges it. A high-quality lithium ion battery charger is essential for maintaining cell health and ensuring safety.

Using an incorrect or generic charger can lead to "thermal runaway" or reduced cycle life. A professional lithium ion battery charger should employ a CC/CV (Constant Current/Constant Voltage) charging algorithm and communicate with the battery's BMS to prevent overcharging. Mottcell provides integrated charging solutions that are specifically tuned to our cell chemistry, ensuring maximum longevity.

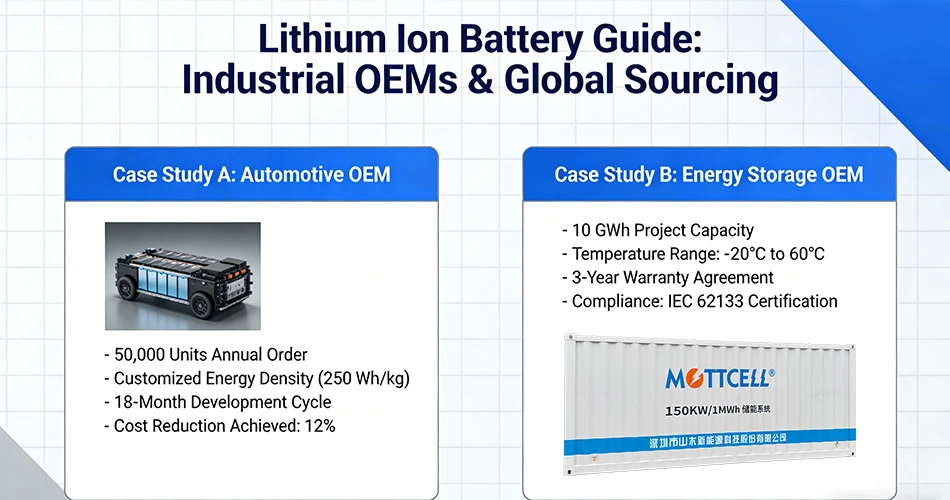

Finding a reliable Lithium ion battery manufacturer is about more than just a quote. It is about a commitment to quality. Mottcell stands out in the global market through:

State-of-the-Art Factory: Our Lithium ion battery factory utilizes automated production lines to ensure that every cell meets strict internal resistance and capacity standards.

Global Certifications: We hold UN38.3, CE, RoHS, and IEC certifications, simplifying the export process for our factory clients.

OEM Customization: From custom casing to proprietary BMS firmware, we provide the tailor-made solutions that modern industries require.

A lithium ion battery is a type of rechargeable battery in which lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. Mottcell utilizes advanced cathode materials to ensure our lithium-ion cells offer the highest stability and energy density in the market.

Yes, when manufactured correctly. At our Lithium ion battery factory, we implement multiple safety layers, including internal separators, pressure relief valves, and intelligent BMS. Mottcell batteries undergo rigorous testing (nail penetration, crush tests, and thermal abuse) to ensure they meet the highest global safety standards.

To properly charge lithium ion battery cells, you must use a dedicated lithium ion battery charger. The process should follow a Constant Current (CC) stage until the battery reaches about 90%, followed by a Constant Voltage (CV) stage. Never leave batteries charging unattended on non-specialized equipment.

Yes, but with restrictions. Generally, lithium-ion batteries must be carried in carry-on luggage, not checked bags. For industrial users shipping high-capacity batteries (over 100Wh), specialized UN38.3 documentation and dangerous goods handling are required. Mottcell provides all necessary certification to help our clients manage logistics safely.

You should never throw a lithium ion battery in the regular trash. They must be taken to specialized recycling centers. As a responsible Lithium ion battery manufacturer, Mottcell advocates for the "circular economy" and partners with global recycling programs to ensure valuable materials like lithium and copper are recovered and reused.

The transition to lithium technology is an opportunity to redefine your product's performance. Whether you need a high-drain lithium ion car battery, a rugged lithium ion deep cycle battery, or a custom-built power system, Mottcell has the expertise and manufacturing power to deliver.

Empower your next project with Mottcell. Contact us

Related News

32650 Lithium Ion Battery Manufacturer for OEM Custom Cells and Packs

10440 Lithium Ion Battery Factory: Inside Look

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

16340 Lithium-Ion Battery Manufacturing Process

Top 18500 Lithium Ion Battery Manufacturer Guide

26700 Lithium Ion Battery Manufacturer for OEM Applications

32700 Lithium Ion Battery Manufacturer for OEM Applications

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer