In the rapidly evolving landscape of energy storage, the cylindrical battery remains the most reliable and widely adopted form factor for industrial applications. From high-torque power tools and automated guided vehicles (AGVs) to grid-scale storage, the structural integrity and thermal efficiency of cylindrical cells provide a unique competitive advantage.

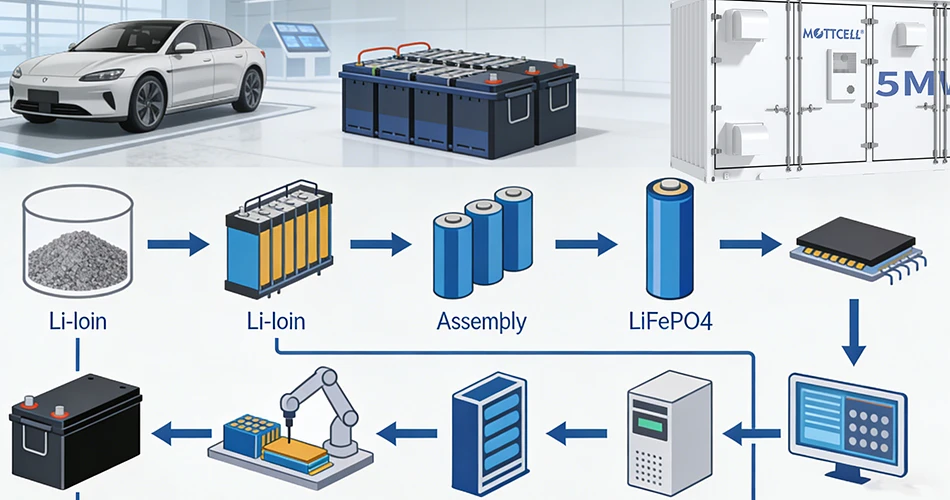

For factory managers, procurement specialists, and product engineers, selecting the right cylindrical lithium ion battery is not just about capacity—it’s about optimizing for safety, mechanical stability, and long-term total cost of ownership (TCO). As a professional cylindrical battery manufacturer, Mottcell provides the technical expertise and high-volume production capabilities required to power the next generation of industrial innovation.

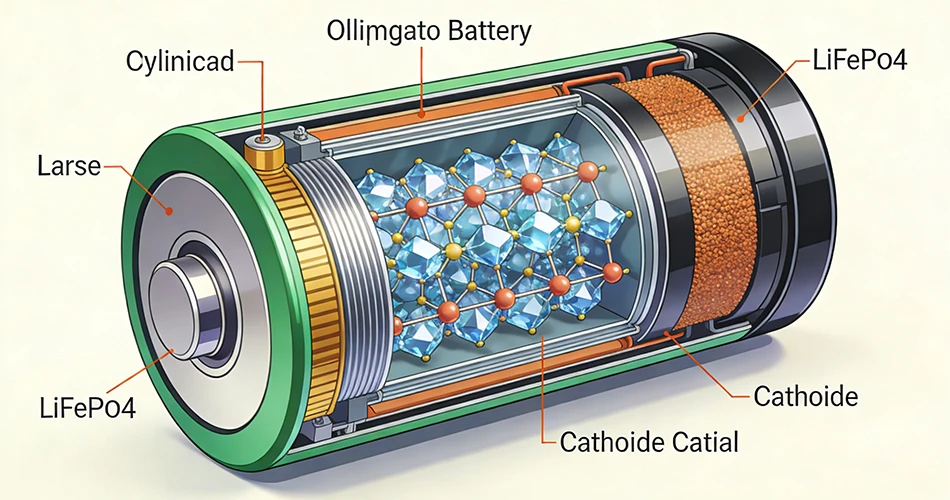

The cylindrical li ion battery (Lithium-Ion) is characterized by its spiral-wound electrode design encased in a rigid metallic cylinder. This standardized geometry—most notably the 18650, 21700, and 4680 formats—has been perfected over decades of manufacturing.

Mechanical Strength: The tubular shape distributes internal pressure evenly, making these cells highly resistant to swelling and mechanical shock.

Thermal Management: The gaps created between cells in a cylindrical battery pack allow for natural airflow and efficient heat dissipation, preventing the "hotspot" issues often found in prismatic designs.

Production Maturity: The automation level in a cylindrical battery factory is among the highest in the world, ensuring superior consistency and lower failure rates for high-volume orders.

Not all cylindrical batteries are created equal. The choice of chemistry dictates the performance profile of your end product.

For industrial environments where safety and longevity are paramount, the cylindrical lifepo4 battery is the gold standard.

Cycle Life: Quality LFP cells can deliver over 4,000 to 6,000 cycles at 80% Depth of Discharge (DoD).

Safety: The phosphate-based cathode is chemically stable and will not catch fire or explode even under extreme abuse.

Ideal For: Solar energy storage, electric forklifts, and medical backup power.

For applications requiring high energy density and compact sizing, traditional cylindrical lithium batteries (using NMC or LCO chemistries) are preferred.

Energy Density: Offers higher watt-hours per kilogram, making them ideal for drones and portable power tools.

Discharge Rate: Li ion cylindrical rechargeable batteries are designed to handle high-drain bursts without significant voltage sag.

As a leading cylindrical battery supplier, Mottcell doesn't just provide cells; we engineer modular and custom cylindrical battery packs tailored to specific OEM requirements.

Incoming Cell Validation: Every cylindrical rechargeable battery is tested for internal resistance and voltage consistency before assembly.

Cell Carriers & Brackets: Rugged frames secure the cylindrical battery cells, providing shock protection and maintaining precise spacing for cooling.

Advanced BMS: The Battery Management System (BMS) monitors the state of charge (SoC) and state of health (SoH) for the entire array.

Electrical Interconnects: High-precision spot welding or laser welding ensures low-resistance connections for high-current throughput.

Industrial buyers often ask: "Why choose cylindrical battery cells over prismatic ones?"

Feature | Cylindrical Battery Cells | Prismatic Battery Cells |

Mechanical Strength | Highest (Rigid Steel/Alu Can) | Moderate (Thinner Shell) |

Thermal Performance | Superior (Natural Air Gaps) | Difficult (Requires Sophisticated Cooling) |

Manufacturing Consistency | High (Proven Standards) | Varies (Complex Design) |

Packing Efficiency | Lower (Round Stacking Gaps) | Highest (Rectangular Stacking) |

Failure Isolation | High (Small Single-Cell Events) | Low (Large Cell Failure Impact) |

In high-vibration industrial settings, cylindrical lithium ion battery modules are typically favored because their rigid structure prevents internal electrode shifting, a common cause of short circuits in other formats.

Choosing the right cylindrical battery supplier can make or break your product's market reputation. At Mottcell, our cylindrical battery factory adheres to ISO 9001 and IATF 16949 standards to ensure every cell meets global industrial benchmarks.

Standardized Formats: We offer high-volume supply of 18650, 26650, 32650, and 32700 cells.

Customization: We design and manufacture cylindrical battery charger systems and integrated PCBA solutions to accompany your power packs.

Sustainability: We focus on the long-term cylindrical battery life, reducing waste through high-cycle-life LFP chemistries.

The cylindrical shape is chosen for its ability to withstand high internal pressures without deforming. This geometry allows for the use of high-speed automated winding processes, making it the most cost-effective and structurally sound way to package energy.

Cylindrical cells use a spiral-wound design in a rigid can, offering excellent cooling and durability. Prismatic cells are rectangular and stacked, offering higher energy density per volume but requiring more complex thermal management to prevent swelling.

LFP (Lithium Iron Phosphate) offers superior safety and cycle life (thousands of cycles), making it ideal for industrial storage. LCO (Lithium Cobalt Oxide) offers higher energy density but has a shorter cycle life and lower thermal stability, commonly used in consumer electronics.

For modern industrial use, cylindrical lithium ion batteries are superior to traditional lead-acid tubular batteries. Lithium offers 10x the cycle life, 1/3 the weight, and zero maintenance requirements, resulting in a much lower total cost of ownership over 5 years.

In the industrial lithium sector, the three primary types (form factors) are cylindrical, prismatic, and pouch cells. Each has specific trade-offs regarding weight, thermal efficiency, and mechanical strength.

Mottcell is a vertically integrated cylindrical battery manufacturer with 18+ years of experience. We provide end-to-end solutions from individual cylindrical rechargeable battery cells to complete cylindrical battery pack design and manufacturing.

The cylindrical battery remains the heart of industrial electrification. Whether you need the high-density power of a cylindrical lithium ion battery for robotics or the ultra-safe longevity of a cylindrical lifepo4 battery for storage, Mottcell has the production capacity and engineering depth to support your mission.

Contact us for a custom [cylindrical battery pack solution]

Related News

Efficient 14650 Cylindrical Battery Factory Insights

Reliable 32650 Cylindrical Battery Factory for OEM Cells and Packs

Efficient AA Cylindrical Battery Factory: Production & Tech

AAA Cylindrical Battery Factory: 3.2V LiFePO4 Specialized Production Base

18500 Cylindrical Battery Factory Insights

22650 Cylindrical Battery Factory for OEM Cell and Pack Supply

26700 Lithium Ion Battery Manufacturer for OEM Applications

2V 10440 Battery: Find Top Cylindrical Battery Factory

14430 Cylindrical Battery Manufacturing Insights

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer