In the competitive world of modern manufacturing and product development, energy storage is no longer just a component—it is a core competitive advantage. For factory owners, OEM engineers, and procurement managers, understanding the landscape of lithium technology is essential to building reliable, high-performance products.

This ultimate guide to lithium batteries is designed to cut through the jargon and provide industrial-grade insights into chemistry types, sourcing strategies, and high-drain applications. Whether you are building medical devices or looking for the best lawn mower battery for a new range of garden equipment, this guide from Mottcell covers it all.

When sourcing power solutions, the choice often boils down to two dominant technologies: li ion and li polymer. While they share similar electrochemical foundations, their physical and performance characteristics vary significantly.

The li ion cells (Lithium-Ion) are typically encased in rigid cylindrical or prismatic metal cans. They use a liquid electrolyte and are prized for their high energy density and cost-effectiveness. Standard formats like the 18650 and 21700 are the workhorses of the industrial world.

Lithium Polymer (Li-Po) batteries utilize a polymer electrolyte in a soft, flexible foil pouch. This allows for ultra-thin profiles and unique shapes, which are critical for wearable tech and slim medical instruments.

The debate of li po battery vs lithium ion usually centers on two factors:

Form Factor: If your device is slim and lightweight, Li-Po is the winner.

Durability: If your device operates in rugged industrial environments, the rigid casing of li ion cells offers better mechanical protection.

When comparing lipo battery vs li ion battery, OEMs must also consider that Li-Ion generally offers a better price-to-capacity ratio for large-scale energy storage.

The landscaping and agricultural equipment sectors are undergoing a massive shift from lead-acid and gas to lithium power. Selecting the best lawn mower battery is now a top priority for manufacturers of garden machinery.

In the past, riding mowers relied on heavy lead-acid batteries that required frequent maintenance and suffered from rapid voltage drops. Today, rechargeable lithium ion cells provide:

Consistent Power: Unlike lead-acid, lithium maintains a steady voltage throughout the discharge cycle.

Rapid Charging: Significantly reduces downtime for commercial landscaping crews.

Weight Reduction: A best riding mower battery based on lithium-ion can be up to 70% lighter, improving vehicle maneuverability.

For heavy-duty equipment, the best lawn tractor battery must handle high vibration and extreme outdoor temperatures. Mottcell specializes in reinforced li ion cells designed specifically for the high-torque requirements of electric lawn tractors, ensuring that your equipment outlasts the competition.

The performance of any battery pack is entirely dependent on the quality of its individual rechargeable lithium ion cells. In a factory setting, "Grade A" cells are the only acceptable standard for long-term reliability.

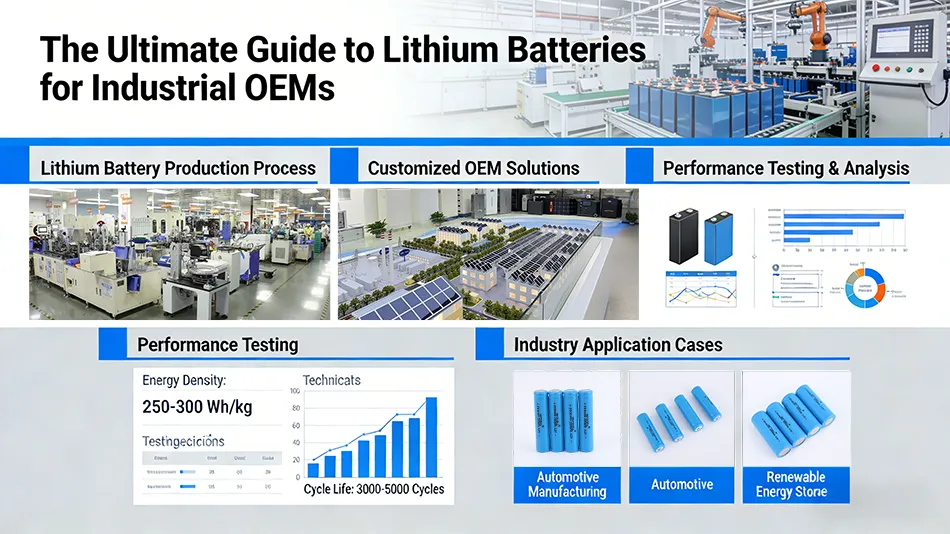

Cycle Life: High-quality rechargeable lithium ion cells should offer at least 500-1,000 cycles for NMC chemistry, and over 3,000 for LiFePO4.

Internal Resistance: Low resistance is crucial for preventing heat buildup during high-current discharge.

Consistency: When building a large pack, every cell must be matched for capacity and voltage to ensure the longevity of the entire system.

Becoming an industry leader requires more than just finding a supplier; it requires a manufacturing partner. As a leading rechargeable lithium ion cells manufacturer, Mottcell emphasizes the "Three Pillars of Industrial Battery Supply":

Safety Certification: Ensure your supplier provides UN38.3, CE, and UL certifications.

BMS Engineering: A lithium battery is only as safe as its Battery Management System.

Supply Chain Transparency: Avoid "gray market" cells. Direct factory sourcing ensures traceability and consistent chemical purity.

While the ultimate guide to lithium batteries focuses on today’s dominant technologies, the industrial landscape is always moving. We are seeing a shift toward high-nickel chemistries for better energy density and the early stages of solid-state development for ultra-safe applications.

However, for 90% of current industrial applications, the choice between li ion and li polymer remains the most practical and cost-effective path for OEMs.

No, they are not exactly the same. While both use lithium ions, the main difference is the electrolyte. Li-Ion uses a liquid electrolyte in a metal case, whereas Li-Po uses a gel-like or polymer electrolyte in a flexible pouch. When comparing lipo battery vs li ion battery, remember that Li-Ion is generally more robust, while Li-Po is more customizable in shape.

It depends on your application:

LiFePO4: Best for safety and ultra-long life (e.g., Energy Storage Systems, best lawn tractor battery).

Li-ion: Best for high energy density at a lower cost (e.g., Laptops, E-bikes).

Li-Po: Best for thin, lightweight devices (e.g., Smartphones, Medical wearables).

If you are an OEM building residential mowers, a high-capacity li ion cells pack is usually the most cost-effective. For commercial use, we recommend LiFePO4 for its ability to handle daily deep discharges for years without significant degradation.

Yes, there are 1.5V rechargeable lithium AA batteries that use internal circuitry to step down the 3.7V lithium cell voltage. However, for industrial products, we recommend designing the device around standard rechargeable lithium ion cells (like the 14500) for better efficiency and higher capacity.

While there are many retail brands, for industrial-scale manufacturing, Mottcell is recognized as a premier provider of high-quality li ion and li polymer solutions. We focus on providing factory-direct, certified power systems for the world's leading equipment manufacturers.

Safety is our priority. At Mottcell, every battery—whether it's a li po battery vs lithium ion—is equipped with a multi-layered BMS to protect against overcharge, over-discharge, and thermal runaway.

This ultimate guide to lithium batteries highlights that the "best" battery is the one that aligns with your product’s specific duty cycle, environment, and budget. Whether you are searching for the best lawn mower battery or need a custom-shaped li po battery, Mottcell has the engineering expertise to help you succeed.

Related News

10440 Lithium Ion Battery Factory: Inside Look

14430 Lithium-Ion Battery Factory: Inside the Production Process

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

26700 Lithium Ion Battery Manufacturer for OEM Applications

AAA Lithium Ion Battery Factory: Specialized 3.2V LiFePO4 Production Base

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer