In the modern industrial landscape, lithium-ion technology powers everything from handheld diagnostic tools to large-scale energy storage systems. However, with high energy density comes the critical responsibility of safety management. For factory owners, procurement managers, and safety officers, understanding lithium battery safety & usage is not just about compliance—it is about protecting assets, ensuring workforce safety, and optimizing the lifespan of your power solutions.

As a leading global manufacturer, Mottcell is committed to providing high-performance cells that meet the most rigorous safety standards. This guide provides an in-depth look at managing various battery formats—from the common rechargeable battery aaa to high-capacity 3.7v rechargeable battery packs—while identifying the root causes of failure and best practices for the workplace.

To maintain a safe workplace, it is essential to understand the technical specifications of the batteries you use. Industrial equipment often utilizes different form factors, each with specific handling requirements.

The 3.7 volt battery is the nominal voltage standard for most lithium-ion chemistry. Whether it is a cylindrical cell or a pouch-style pack, this voltage represents a balance between stability and power output. In many factory sensors and portable devices, the 3.7v rechargeable battery is the preferred choice due to its high energy-to-weight ratio.

For smaller handheld devices, the rechargeable battery aaa has evolved. While traditional NiMH cells are common, the battery aaa lithium variant is increasingly popular in industrial settings. These lithium ion aaa rechargeable cells offer:

Stable Voltage: Unlike alkaline, they maintain peak power throughout the discharge cycle.

Low Self-Discharge: Perfect for emergency equipment that stays in storage.

AAA Battery Dimensions: Standardized at approximately 10.5mm in diameter and 44.5mm in length, ensuring compatibility across all legacy "Triple A" devices.

Innovation in charging has led to the rise of rechargeable battery and usb integration. Many modern li ion aaa rechargeable batteries now feature built-in ports, allowing for direct charging without a dedicated external cradle.

The transition to type c rechargeable batteries has revolutionized factory tool maintenance.

Universal Compatibility: Charge your 3.7v li ion rechargeable battery using the same cables as your industrial tablets.

Faster Charging: Type-C protocols support higher current, reducing the downtime of critical handheld tools.

Integrated Protection: Mottcell’s rechargeable triple a battery products with USB-C include internal microchips to prevent overcharging and short circuits at the cell level.

One of the most frequent safety concerns reported by factory staff is battery deformation. Understanding what causes a battery to swell is vital for preventing thermal runaway.

Battery swelling (or "puffing") is caused by gas generation inside the cell. This is typically a result of:

Overcharging: If a 3.7 volt battery is charged beyond its rated voltage (usually 4.2V max), the electrolyte begins to decompose, releasing gases like carbon dioxide and methane.

Heat Exposure: Operating a 2600 mah battery in high-temperature environments (above 60°C) accelerates chemical breakdown.

Deep Discharge: Allowing a 3.7v rechargeable battery to drain completely can cause permanent chemical instability, leading to gas buildup when it is finally recharged.

Manufacturing Defects: Low-quality 3.7v batteries from uncertified suppliers may contain impurities that trigger internal side reactions.

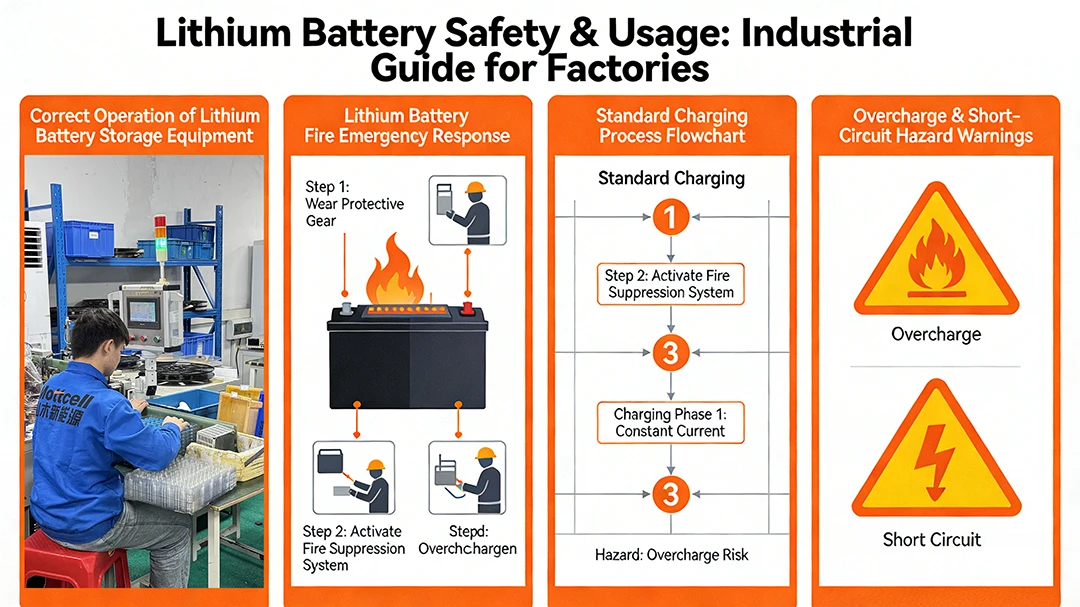

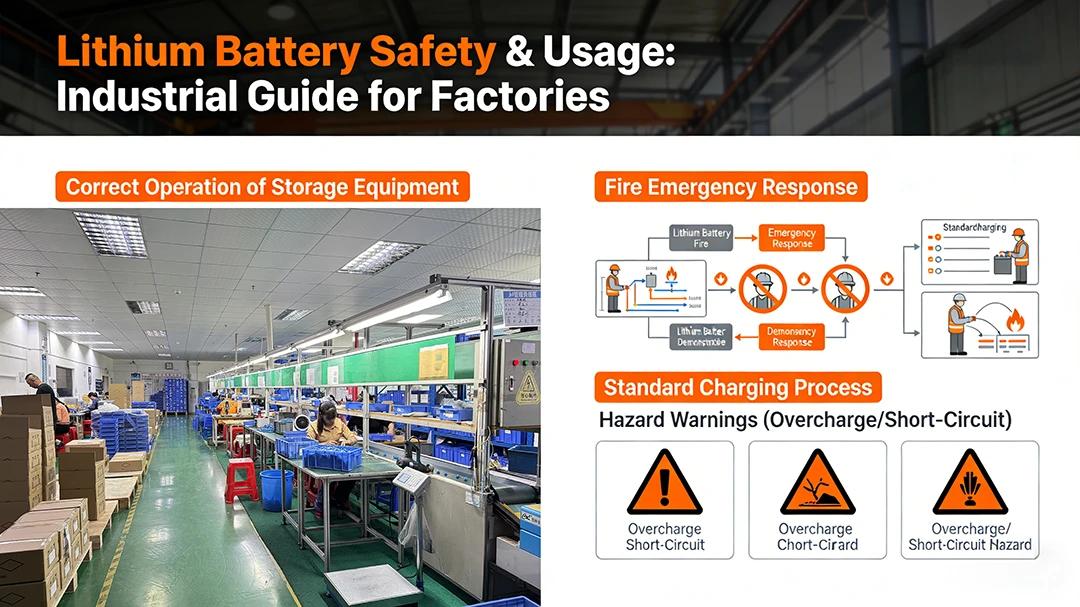

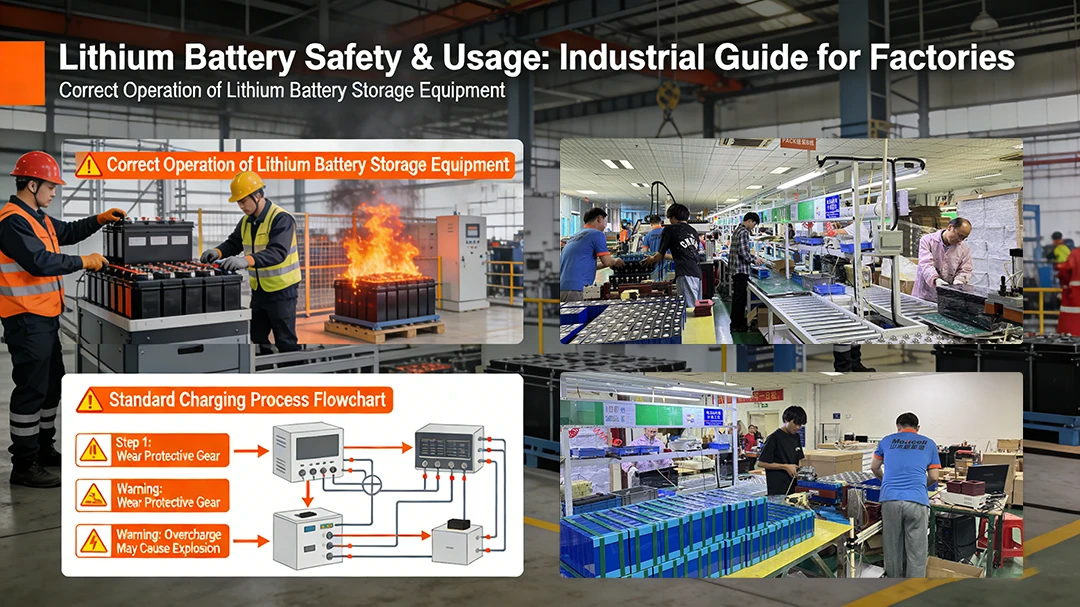

To ensure lithium battery safety & usage protocols are effective, industrial facilities should implement the following "Hierarchy of Safety":

Temperature Control: Store rechargeable triple a battery stocks in a cool, dry location (15°C to 25°C). Avoid direct sunlight or proximity to heat-generating machinery.

Dedicated Charging Stations: Charge large 3.7v li ion rechargeable battery packs on non-combustible surfaces (like metal or stone) and away from emergency exits.

The 2600 mAh Battery Rule: For high-capacity cells, like the 2600 mah battery, ensure the charger is specifically rated for that capacity to avoid over-current stress.

Staff should be trained to inspect the aaa battery dimensions and casing of all cells. If a cell appears thicker than its standard aaa battery dimensions, it must be decommissioned immediately.

Industrial lithium batteries are classified as "Dangerous Goods" (Class 9).

UN38.3 Certification: Every 3.7v li ion rechargeable battery manufactured by Mottcell undergoes UN38.3 testing to ensure it can safely withstand vibration, shock, and pressure changes during transport.

Labeling: All bulk shipments of lithium ion aaa rechargeable cells must be clearly labeled with hazard warnings and handling instructions.

As explained, what causes a battery to swell is primarily gas accumulation from electrolyte decomposition. This is usually triggered by overcharging, excessive heat, or physical damage. At Mottcell, we use high-purity electrolytes and advanced separators to significantly reduce the risk of gas generation under normal operating conditions.

The safest method is to use a "Smart Charger" that is specifically designed for the battery's chemistry and voltage. Never leave battery packs charging unattended overnight, and ensure the charging area is well-ventilated. Using Mottcell’s rechargeable battery and usb integrated cells can also add a layer of protection through their internal voltage-limiting chips.

If a 3.7v rechargeable battery is punctured, leaking, or smoking, do not touch it with bare hands. Use non-conductive tools to move it to a fireproof container (like a metal bucket filled with sand) and isolate it outdoors. Contact a professional hazardous waste disposal service immediately.

Yes. International regulations (IATA, IMDG) require that lithium batteries be tested under UN38.3 standards. Mottcell provides full compliance documentation for all our li ion aaa rechargeable batteries and high-capacity cells, ensuring seamless global logistics for our OEM partners.

Mastering lithium battery safety & usage is a continuous process of education and quality sourcing. By understanding the causes of failure—like what causes a battery to swell—and utilizing modern standards like type c rechargeable batteries, your factory can maximize efficiency while minimizing risk.

Mottcell is your partner in industrial power. We provide the Grade-A 3.7v li ion rechargeable battery and aaa battery lithium solutions you need, backed by the certifications your safety department requires.

Related News

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

26700 Lithium Ion Battery Manufacturer for OEM Applications

AAA Lithium Ion Battery Factory: Specialized 3.2V LiFePO4 Production Base

High-Quality 3.2V 16340 Lithium Ion Battery Factory

32650 LiFePO4 Battery Factory for Custom OEM Solutions

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

26700 Lithium Ion Battery Manufacturer for OEM Applications

AAA Cylindrical Battery Manufacturer for OEM Factories

Popular Battery Sizes & Ratings: The Strategic Industrial Guide | Mottcell

Lithium Battery Safety & Usage: Industrial Guide for Factories

Battery Types: Alkaline vs Rechargeable Industrial Guide | Mottcell

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell