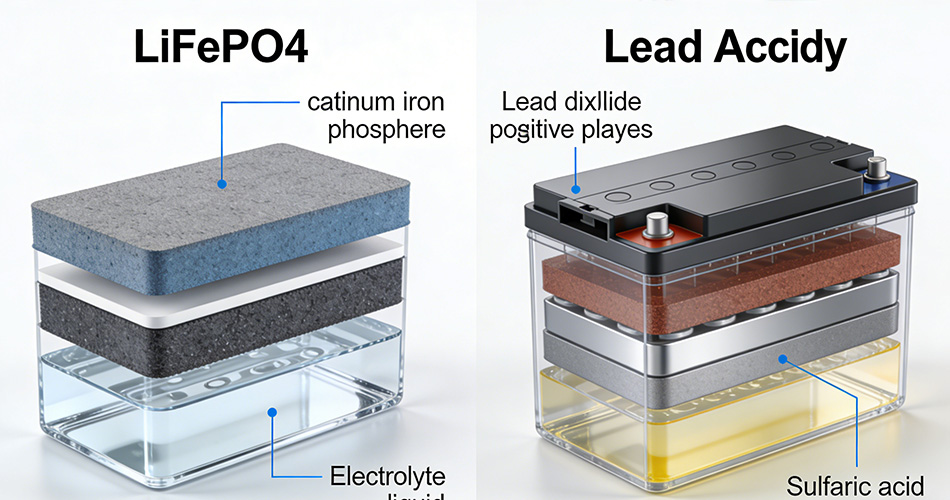

Over the past decade, the global industrial landscape has undergone a radical energy transition. Factory OEMs and industrial operators are rapidly moving away from legacy Lead-Acid technology in favor of the more robust and efficient Lithium Iron Phosphate (LiFePO4) solutions.

When you evaluate LiFePO4 vs Lead Acid, you are not just comparing two battery chemistries; you are comparing two different operational philosophies. For Automated Guided Vehicles (AGVs), large-scale Energy Storage Systems (ESS), and heavy-duty machinery, understanding the technical nuances of lithium LiFePO4 vs lead acid is the key to optimizing equipment uptime and long-term profitability.

The LiFePO4 battery has emerged as the clear frontrunner in the industrial sector. Unlike traditional lithium-ion chemistries (like NCM) that utilize cobalt, LiFePO4 is chemically stable, environmentally sustainable, and exceptionally cost-effective over its lifecycle.

As a specialized LiFePO4 battery manufacturer, Mottcell has dedicated nearly 20 years to perfecting this chemistry. Our facilities—ranging from our 3.2V AA LiFePO4 battery factory producing precision cylindrical cells to our large-format pack assembly lines—focus on delivering what industrial clients need most: high energy density paired with uncompromising thermal safety.

In the LiFePO4 battery vs lead acid debate, the most striking disparity lies in the cycle life and Depth of Discharge (DoD) capabilities.

A standard lead-acid battery typically offers 300 to 500 cycles at a 50% discharge depth. In contrast, a high-quality battery from a professional LiFePO4 battery factory can easily provide 4,000 to 6,000 cycles at 80% DoD.

The Business Impact: If a device is charged once daily, lead-acid batteries require replacement every 1.5 years. A LiFePO4 system remains operational for over 10 years, drastically reducing replacement frequency.

Lead-acid batteries require regular "watering," electrolyte checks, and specialized ventilated rooms to manage explosive gassing. Lithium wins on operational simplicity. LiFePO4 battery vs lead acid safe operation means zero fluid maintenance, lower labor costs, and a cleaner factory environment free from acid corrosion risks.

For mobile industrial applications, LiFePO4 weight vs lead acid is a decisive factor. Lithium batteries are approximately one-third the weight of lead-acid counterparts for the same usable capacity.

Result: This translates to lower energy consumption for AGVs, higher payload capacities for mobile robots, and improved ergonomics for portable medical instruments.

Many industrial procurement managers consider LiFePO4 vs gel battery for deep-cycle needs. Gel batteries are an improvement over flooded lead-acid because they are spill-proof and vibration-resistant. However, they still suffer from "Peukert’s Law," where usable capacity drops significantly under high discharge rates.

LiFePO4 vs gel battery comparisons consistently show that lithium maintains a higher, more stable voltage platform throughout the discharge cycle. This ensures that sensitive industrial electronics do not suffer from brownouts or reboots when the battery runs low.

Charging protocols directly impact factory uptime. The LiFePO4 vs lead acid charging differences are game-changing:

Energy Efficiency: Lead-acid charging is only 70-85% efficient due to heat loss. LiFePO4 is 98% efficient, meaning almost all paid electricity is stored as usable energy.

Fast Charging: As a premier 3.2V AA LiFePO4 battery manufacturer, Mottcell develops systems that support high-current charging. While lead-acid requires 8-12 hours for a full soak, LiFePO4 can be fast-charged in 1-2 hours, enabling "opportunity charging" during staff breaks.

No Memory Effect: Lead-acid batteries must be fully charged regularly to prevent sulfation. LiFePO4 thrives in a Partial State of Charge (PSOC), making it ideal for solar applications where full sun is not always guaranteed.

In the 12V/24V industrial market, the 100Ah LiFePO4 vs lead acid battery is the most common benchmark.

Usable Capacity: A 100Ah lead-acid battery provides only 50Ah of usable power to prevent premature failure.

The Lithium Advantage: A 100Ah LiFePO4 battery provides up to 95Ah of usable power.

Conclusion: One lithium battery effectively replaces two lead-acid batteries, saving 50% in footprint and 70% in weight for factory setups.

While lead-acid remains the legacy choice for starting engines, the LiFePO4 vs lead acid car battery debate is moving into industrial logistics. For heavy-duty forklifts and hybrid factory equipment, lithium’s massive cold-cranking amps (CCA) and low self-discharge rate ensure that equipment starts instantly, even after weeks of storage.

In a professional factory, safety is the foundation of operation. LiFePO4 vs lead acid safety involves managing different risk profiles:

Lead Acid: Risk of acid spills, heavy metal contamination, and hydrogen gas emissions.

LiFePO4: The most stable lithium chemistry available. It will not catch fire or explode even under extreme stress (puncture or high temperature).

Mottcell integrates a smart BMS (Battery Management System) into every pack. This provides "active safety"—monitoring voltage and temperature in real-time—a level of intelligence that traditional lead-acid batteries cannot offer.

The LiFePO4 vs lead acid discharge curve proves why lithium is the superior choice for high-performance machinery.

Lead-Acid: Voltage drops steadily as the battery drains. This causes equipment like forklifts to slow down and lose torque as the shift progresses.

LiFePO4: The curve is remarkably flat. It provides 100% power and consistent torque until the battery is nearly empty, ensuring peak factory productivity from start to finish.

The lifepo4 vs lead acid energy density advantage allows for more compact industrial designs. For makers of light electric vehicles and robots, LiFePO4 vs lead acid for motorcycle or AGV applications enables a 70% reduction in battery volume. As a 3.2V AA LiFePO4 battery supplier, we provide the modular cells needed to build high-density power banks for these precision systems.

While the initial price of lithium is higher, the TCO is the metric that matters to a factory.

Metric | Lead Acid (SLA) | LiFePO4 (Mottcell) |

Initial Cost | Low | Moderate |

Cycle Life | 300 - 500 | 4,000 - 6,000 |

Maintenance | High (Labor/Water) | Zero |

Cost Over 5 Years | Very High (3+ Replacements) | Low (0 Replacements) |

Over a 5-year period, the cost of lithium lifepo4 vs lead acid is actually 40-60% lower when factoring in lifespan and maintenance savings.

A: Yes. For factory Energy Storage Systems (BESS), LiFePO4 offers superior ROI due to higher cycle efficiency and a much smaller footprint.

A: Generally, yes. However, you must verify that your charger is compatible with the lifepo4 vs lead acid charging profile to ensure the battery reaches its full 10-year lifespan.

A: The main hurdle is the higher upfront cost and the fact that lithium cannot be charged in sub-freezing temperatures. Mottcell solves this by offering battery packs with integrated heating elements for cold-climate use.

A: Lithium is far superior. Lead-acid plates can break under heavy vibration, whereas LiFePO4 vs lead acid tests show that lithium's solid-state-like construction is much more durable in industrial vehicles.

Transitioning to lithium is a strategic investment in reliability. Mottcell is not just a LiFePO4 battery manufacturer; we are your technical partner. Whether you need a 3.2V AA LiFePO4 battery supplier for small-scale devices or high-capacity industrial solutions, we have the expertise to power your success.

Contact us today at

Related News

Top 10440 LiFePO4 Battery Manufacturer Guide

14500 LiFePO4 Battery: Factory Insights & Safety

Top 14650 LiFePO4 Battery Manufacturer

Top 10440 LiFePO4 Battery Manufacturer Guide

16340 Lithium-Ion Battery Manufacturing Process

Reliable 22650 LiFePO4 Battery Factory for Wholesale Supply

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Lithium Polymer vs Lithium Ion: The Professional Industrial Guide | Mottcell

The Ultimate Guide to Lithium Batteries for Industrial OEMs | Mottcell

Common Small Battery Types Explained: Industrial Sourcing Guide

Lithium Ion Battery Guide: Industrial OEMs & Global Sourcing | Mottcell

Top Cylindrical Battery Manufacturer: Li-ion & LiFePO4 Cells | Mottcell

18650 Batteries Guide: Industrial Li-ion & LiFePO4 Manufacturer