In the rapidly evolving industrial landscape, the shift toward electrification is no longer a trend—it is a strategic necessity. Whether you are developing high-precision medical instruments, rugged outdoor equipment, or large-scale energy storage systems, the quality of your power source dictates the success of your project. Lithium ion battery solutions have become the gold standard, offering unparalleled energy density and reliability.

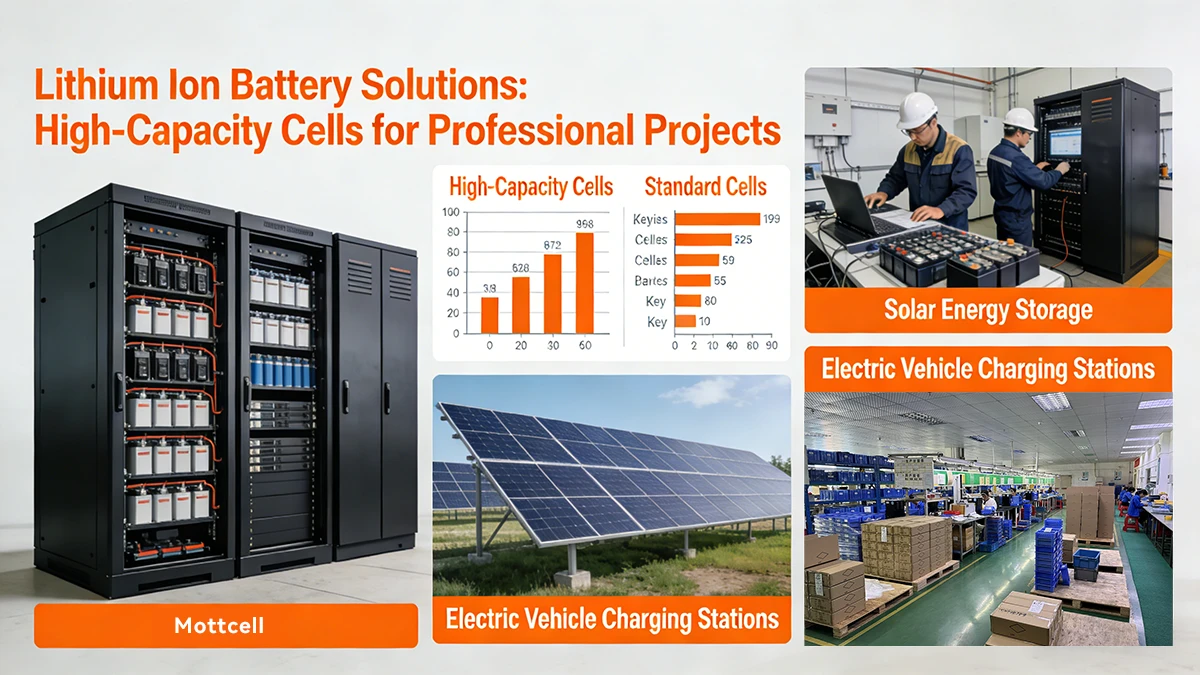

For procurement managers and engineers in a factory setting, selecting the right cell format is critical. At Mottcell, we specialize in high-capacity, professional-grade rechargeable lithium ion battery technology, providing the backbone for global OEM innovations.

A lithium ion battery works by moving lithium ions between the anode and cathode through a micro-porous separator. This chemical movement allows for a high number of charge-discharge cycles—often exceeding 500 to 1,000 full cycles—compared to traditional lead-acid or nickel-based systems. Within the professional sphere, we see a diverse range of formats tailored to specific volumetric and power requirements, ensuring that every industrial application has an optimized energy source.

The AA Lithium ion battery (often categorized as the 14500 size in Li-ion chemistry) is perhaps the most recognizable format. Unlike consumer-grade alkaline AA cells, which suffer from significant voltage sag under load, the lithium-ion version provides a much more stable voltage curve.

Stable Discharge: While alkaline cells drop from 1.5V to 0.9V quickly, a rechargeable lithium ion battery in AA format maintains a consistent output, ensuring industrial handheld scanners and wireless transmitters operate at peak signal strength.

Operational Efficiency: For factories, this means fewer battery swaps and reduced maintenance overhead. By replacing thousands of disposables with a high-cycle AA Lithium ion battery fleet, companies significantly lower their environmental footprint and long-term procurement costs.

When space is at a premium, the AAA Lithium ion battery (equivalent to the 10440 size) offers a lightweight solution without sacrificing discharge performance.

Precision Engineering: Often utilized in precision diagnostic tools, miniature IoT sensors, and high-intensity LED borescopes, these cells provide the high-voltage discharge necessary for modern digital circuitry.

Weight Sensitivity: In wearable industrial tech, the weight reduction offered by the AAA Lithium ion battery compared to NiMH alternatives reduces user fatigue while maintaining the familiar, easy-to-replace Triple-A form factor.

For professional projects, "standard" is never enough. Mottcell’s industrial rechargeable lithium ion battery solutions often include integrated Safety Data Sheets (SDS) compliance and physical protection layers:

PTC (Positive Temperature Coefficient): A resettable fuse that protects against over-current and overheating.

Pressure Relief Vents: Designed to safely exhaust gas in the rare event of a short circuit, preventing casing rupture.

BMS Integration: Most of our professional AA and AAA lithium solutions are designed to work seamlessly with Battery Management Systems that prevent over-voltage during the charging phase.

| Feature | AA Lithium-Ion (Professional) | AA Alkaline (Consumer) | AA NiMH (Rechargeable) |

| Nominal Voltage | 3.6V - 3.7V | 1.5V (Drops rapidly) | 1.2V |

| Cycle Life | 500+ Cycles | Single Use | 300-500 Cycles |

| Energy Density | Very High | Moderate | Low |

| Leakage Risk | Near Zero (Rigid Case) | High (Potassium Hydroxide) | Low |

| Best Use Case | Precision OEM / High-Drain | Remote Controls | Low-Cost Backup |

Beyond standard consumer sizes, industrial projects often require specialized cylindrical cells that offer specific power-to-weight ratios and discharge profiles. Choosing the right "niche" format allows engineers to optimize the internal footprint of a device while maximizing output.

The 14500 Lithium ion battery shares the exact dimensions of a standard AA battery (14mm x 50mm) but operates at a nominal 3.7V—more than double the voltage of alkaline or NiMH cells.

Engineering Advantage: This allows designers to achieve higher motor speeds or brighter LED outputs without increasing the number of cells in series. It is an essential component for engineers who need to "overclock" the performance of a device without redesigning a legacy battery compartment.

Industrial Use Cases: High-lumen tactical lighting, portable medical motors, and high-precision handheld signal testers.

The 10440 Lithium ion battery mirrors the AAA size (10mm x 44mm).

Micro-Protection Circuits: As a leading provider of the rechargeable lithium ion battery, Mottcell ensures that even our smallest cells are equipped with ultra-thin PCB protection. This prevents over-discharge in sensitive electronics, a common issue in micro-power applications.

Industrial Use Cases: Ultra-slim industrial probes, miniature wireless IoT modules, and sleek medical diagnostic pens.

For applications requiring massive current draw and extended runtime, the 26650 Lithium ion battery is the undisputed champion. With a diameter of 26mm, it offers nearly double the volume of the standard 18650.

Current Handling: The larger surface area of the 26650 Lithium ion battery allows for superior thermal dissipation.

Industrial Use Cases: Heavy-duty portable machinery, electric floor scrubbers, high-intensity searchlights, and compact LEV (Light Electric Vehicle) battery packs.

| Cell Type | Dimensions (DxH) | Nominal Voltage | Average Capacity | Best For |

| 10440 | 10mm x 44mm | 3.7V | 320mAh - 600mAh | Ultra-slim IoT & Micro-medical |

| 14500 | 14mm x 50mm | 3.7V | 800mAh - 1200mAh | Tactical gear & Portable tools |

| 26650 | 26mm x 65mm | 3.7V | 4500mAh - 5500mAh | EV power & Industrial motors |

To provide a more technical and authoritative perspective for your industrial audience, we can expand this section by focusing on thermal stability, discharge characteristics, and economic ROI.

Here is the enriched and expanded section for your article:

Choosing the right format is only half the battle; understanding the underlying chemistry and system integration is what ensures long-term safety, regulatory compliance, and peak performance. In an industrial environment, the chemical composition determines how a battery responds to heat, high-current draws, and thousands of duty cycles.

For projects where safety and cycle life are the absolute priorities, the lithium iron phosphate battery (LFP) is the undisputed choice for professional engineering.

Unmatched Thermal Stability: While traditional cobalt-based cells can reach thermal runaway at lower temperatures, the lithium iron phosphate battery features a stable P-O bond. This makes it virtually non-combustible, even under physical puncture or extreme electrical abuse.

Extended Service Life: A standard LFP cell can endure over 3,000 to 5,000 full cycles while maintaining 80% of its original capacity. This makes it the perfect lithium ion battery for inverter systems, heavy-duty robotics, and stationary solar storage where the goal is a 10-year+ service life.

When your project requires a non-cylindrical shape or ultra-lightweight construction, the lithium polymer ion battery (Li-Po) offers ultimate design flexibility.

Space Optimization: Encased in a soft, laminated aluminum foil pouch rather than a rigid metal can, the lithium polymer ion battery can be manufactured in ultra-thin profiles (down to 1mm).

Custom Form Factors: This chemistry allows for curved or irregularly shaped housings common in modern wearable industrial tech, tactical headsets, and slim-profile handheld diagnostic tablets. At Mottcell, we provide bespoke Li-Po dimensions to ensure your power source fits your design, not the other way around.

In the context of factory energy management, the lithium ion battery for inverter use and Energy Storage Systems (ESS) has moved from a backup luxury to an economic necessity.

Peak Shaving and Load Leveling: These systems allow for "peak shaving," a strategy where the factory discharges stored lithium power during expensive peak-demand hours to avoid high utility surcharges.

Seamless Integration: Modern rechargeable lithium ion battery racks are designed for modularity. As your factory grows, you can scale your ESS capacity in parallel.

BMS Intelligence: Every Mottcell ESS solution is governed by a sophisticated Battery Management System. This AI-driven layer monitors cell balancing, SOC (State of Charge), and SOH (State of Health), providing real-time data to your factory's central management console.

| Chemical Type | LiFePO4 (Phosphate) | Li-Polymer (NMC/LCO) | Li-ion (Cylindrical NMC) |

| Safety Level | Exceptional (Non-flammable) | Moderate (Pouch expansion) | High (with CID/PTC vents) |

| Energy Density | Moderate | High | Very High |

| Cycle Life | 3,000 - 5,000+ | 500 - 800 | 800 - 1,200 |

| Best Application | Lithium ion battery for inverter / AGV | Wearable Tech / Slim Tablets | Power Tools / Medical Devices |

A high-quality cell is only as good as the system that maintains it. Using a certified lithium ion battery charger is essential for professional projects. A professional lithium ion battery charger monitors the voltage of each individual cell, preventing overcharging and "thermal runaway," which are the primary causes of battery failure in industrial settings.

A lithium-ion battery is a type of rechargeable battery in which lithium ions move from the negative electrode to the positive electrode during discharge and back when charging. It is the preferred technology for professional projects due to its high energy density and lack of "memory effect."

This usually refers to shipping and airline restrictions. Because lithium-ion batteries contain high energy and flammable electrolytes, they are classified as "Dangerous Goods." However, Mottcell’s products undergo rigorous UN38.3 testing to ensure they meet all international safety standards for global transport.

Yes. A "lithium battery" is typically a primary (non-rechargeable) battery using lithium metal. A "lithium-ion battery" is a rechargeable lithium ion battery system. For most professional and factory applications, the rechargeable lithium-ion system is the more cost-effective and sustainable choice.

The primary disadvantage is their sensitivity to extreme heat and overcharging, which can lead to safety risks. This is why Mottcell integrates high-end Battery Management Systems (BMS) and recommends only using a verified lithium ion battery charger to mitigate these risks.

At Mottcell, we don't just supply cells; we provide comprehensive lithium ion battery solutions. Whether you need the precision of a 10440 Lithium ion battery, the versatility of an AA Lithium ion battery, or the rugged power of a lithium iron phosphate battery, our engineering team is ready to support your factory’s next big project.

Related News

18650 Batteries: Sizes & Uses Guide for Industrial OEMs | Mottcell

32650 Lithium Ion Battery Manufacturer for OEM Custom Cells and Packs

10440 Lithium Ion Battery Factory: Inside Look

22650 Lithium Ion Battery Manufacturer for Custom Cylindrical Cells and Packs

16340 Lithium-Ion Battery Manufacturing Process

Top 18500 Lithium Ion Battery Manufacturer Guide

26700 Lithium Ion Battery Manufacturer for OEM Applications

32700 Lithium Ion Battery Manufacturer for OEM Applications

Reliable 4860 Lithium Ion Battery Manufacturer and OEM Factory

18650 Batteries: Sizes & Uses Guide for Industrial OEMs | Mottcell

Lithium Ion Battery Solutions: High-Capacity Cells for Professional Projects

AAA Cylindrical Battery Manufacturer for OEM Factories

Popular Battery Sizes & Ratings: The Strategic Industrial Guide | Mottcell

Lithium Battery Safety & Usage: Industrial Guide for Factories

Battery Types: Alkaline vs Rechargeable Industrial Guide | Mottcell

Comparing Rechargeable Battery Types: Li-Ion vs NiMH Industrial Guide

Top AA LiFePO4 Battery Manufacturer: High-Performance 3.2V Custom Solutions